Digital vs. Flexo: Which Product Label Printing Method Is Better?

Marketing your business is easier when you use custom labels. These labels contain your business or product name along with your company logo, contact channels, and other brand-specific elements. Custom labels are a great way to make a lasting impression on your customers, especially if your product is available in a physical store.

Product label production uses different technologies, and knowing what’s suitable for your branding can help your merchandise stand out in the aisles. Proper labels can make your product shine in the spotlight.

There are two common types of custom labels for product label printing: digital and flexo. Since producing product labels via digital printing and flexography requires different materials and processes, you need to know how they stack up against each other so you can choose between the two.

Digital Printing vs. Flexographic Printing

Comparing digital printing and flexo printing involves looking at several factors, such as the type of packaging material, design flexibility, size of the label, number of labels to be printed, and production timeline, among others. Below is a breakdown of the various aspects of digital and flexo printing work—including their pros and cons—and when it is best to use one over the other.

Digital Printing

Digital printing is printing an electronic file on a material of your choice, which is typically done using inkjets. The technique involves applying electrical charges to a photo imaging plate (PIP) to attract a special type of ink. As the PIP moves through the press to process the digital file from a computer, the ink reverses the electrical charge and transfers the text (or type, as commonly referred to in printing), image, and artwork onto the label.

Digital Printing for Product Labels: Pros and Cons

Digital presses are high-performing machines that create premium-quality images for your product labels. It can be used on a wide range of materials or substrates—such as cotton, paper, and Sintra boards—with excellent color calibration, thanks to consistent ink density during the entire print run.

It’s fast to print product labels on digital presses too. Once the artwork is electronically available, the project prints directly. Because of the minimal setup time, digitally printed labels can offer a quick turnaround for rush label printing jobs.

You can also personalize your product labels through digital printing. Remember Coca-Cola’s “Share a Coke” campaign? The beverage company gained high promotional mileage by printing the manufacturing label for every bottle with a different person’s name on it. This can only be done quickly and cost-effectively through digital print. The same is true for products that should be uniquely identified, a process called serialization.

On the downside, digital printing can incur higher costs if you require large-volume production since you’re paying a fixed rate per piece of the label. The more copies you order, the higher the total price is. Digital printing is the ideal printing solution for low-volume orders or short to medium print runs.

Another con is that digital print often struggles to hit near-perfect color match, since you can’t load in custom inks for each job. Instead, digital print uses many small dots of just a few pre-determined ink colors to create the appearance of most other colors. Many consumers can’t tell the difference, but it’s a valid consideration for premium brands.

If your digital labels require lamination, they will go to a laminating machine to complete the finishing work, which is an extra step in the production process.

Best Uses of Digital Printing for Labels

Digital printing is best for these product and packaging labels:

- Bottled food products

- Wines, beers, and other beverages

- Folding cartons and corrugated packaging

- Gums and candies

- Health and personal hygiene items

- Food pouches

- Grocery labels

- Custom sheeted retail labels

- Security labels and tags

Flexography

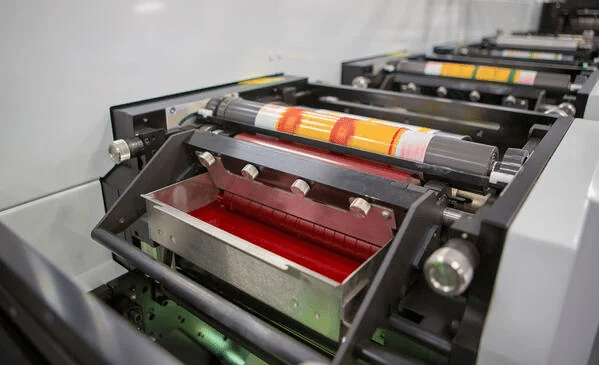

Flexography printing involves using rubber or plastic plates with tiny indentations to carry the text or image and press ink on the materials that your product labels are printing on. The concept behind flexography is similar to how a rubber stamp works, except that the plates rotate on high-speed cylinders to facilitate the transfer of type or artwork.

Flexo plates are customized since one color in the CMYK color model requires one separate plate. Thus, the more colors your product labels need, the more plates the printing company has to create.

Flexography for Product Labels: Pros and Cons

Flexography is a high speed and economical method of printing. Flexo presses can turn out large volumes of your product labels in high-speed production, so you get more value for money. Compared to digital printing, where the per-unit printing cost changes very little based on the volume of your orders, you’ll be paying far less per-label on big flexo printing jobs.

The printing quality in flexo is comparable to digital printing in most applications, owing to the wide variety of label and packaging materials and ink types suitable for this technique. Very small text, below font size 10, becomes difficult for flexo to match the quality of high-end digital print jobs. Finishing effects are easy to integrate since flexo printing engines can hold laminating and foiling solutions, which often comes in handy for premium products.

Flexo plates can match the exact color of your product labels too. However, since each color needs a separate plate, you may see an increase in custom plates’ manufacturing cost—especially if you have a colorful or intricate design on your product label. Flexography is best for product labels that don’t use too many colors or complex graphic design elements.

Setting plates to accommodate changes in color applications or fixing typos can also be time-consuming, so be prepared in case of updates or revisions.

Best Uses of Flexography for Labels

These products commonly use flexo label printing:

- Liquor bottles

- Food packaging

- Cosmetics labels

- Paper towels

- Pizza boxes

- Candy wrappers

- Embossed products

Take Your Pick: Digital or Flexo

Each business has different needs that could impact your decision in choosing between digital and flexo printing for your product labels. Consider factors like the project’s size, design complexity, turnaround time, color registration, customization, available materials, and cost when deciding.

It would be best if you consult with printing experts too. We at Meyers will help you assess your business’ specific needs and suggest professional printing solutions to bring your product labels to life. Ask us about your options.