How Does Offset Printing Work? An In-Depth Guide

Offset printing, also known as lithography, offset lithography, or litho-offset, is among the most popular printing techniques across industries. Professional printers often consider offset printing the standard for product packaging printing in the industry because of its ability to produce large volumes while maintaining quality.

Businesses often use offset printing to create their office stationery, marketing brochures, cards, and product labels for cartons or boxes. Publishing companies also commonly use offset printing to quickly produce thousands of magazines and newspapers.

In certain circumstances, offset printing is more cost-efficient than digital printing. But how exactly does offset printing work? Why should one consider it for packaging and high-volume projects?

What is Offset Printing?

Offset printing is a method that uses a sequence of rotating cylinders to stamp ink onto the receiving media—most often, paper. The method’s efficiency makes it ideal for print orders greater than 1,000 copies. One may also use other materials such as wood, cloth, or leather.

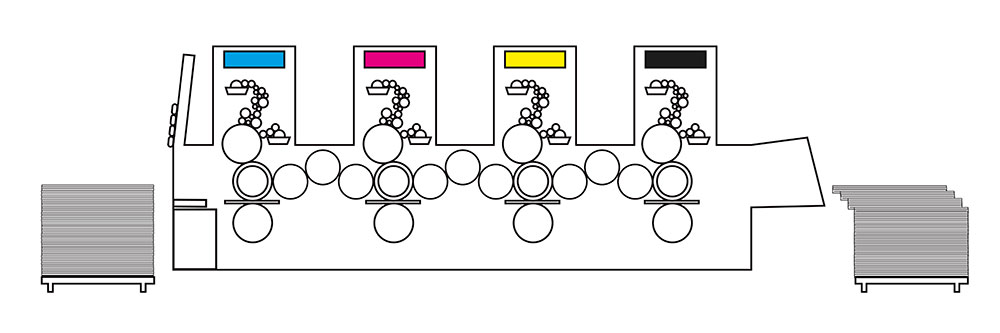

Each color of the print is applied separately in offset printing, depending on the four main colors: cyan, magenta, yellow, and black (CMYK).

One must not make the mistake of confusing offset printing and flexo printing. Flexo printing, also known as flexography, is on par with offset printing because both require a system of cylinders and plates to print onto the material. Businesses primarily use flexo printing for non-porous materials, including foil and film.

3 Different Types of Offset Printing

Businesses look to different types of offset printing depending on their desired results.

1. Web

In web offset printing, printers print on a long, continuous sheet of paper, cut and separated once printed. This type of offset printing is ideal for large-quantity orders, such as books, magazines, or newspapers.

2. Sheet-fed

Sheet-fed offset printing already has its pages cut before the printer receives them. Printers have a sheet feeding machine that blows an air jet to push a single sheet of paper through the machine. The devices also have detectors that automatically shut the printer off if it recognizes that one sheet is too thick, meaning it is still attached to another.

3. Quick-set

Quick-set printing machines use quick-set ink that sets quickly and dries slowly, allowing it to save ink. It is an ideal printing type for periodicals, instruction manuals, and trademarks. These also dry faster compared to other offset printing methods, allowing for a much faster turnaround time.

Before deciding which method is ideal for reaching one’s desired results, it helps to understand how offset printing works.

How Does Offset Printing Work?

Regardless of the printing method one intends to use, the process follows the same steps. Take a look below to understand how offset printing works.

Preparing

Designers and operators must first digitally prepare the image they are printing.

This process involves creating different versions of the image highlighting the CMYK color groups. Each version of the image is laser etched onto an aluminum plate, which wraps around the plate cylinder.

Since this printing method prints colors one at a time, operators adjust the four color groups per printer to produce an accurate and vibrant image for the client. These adjustments include increasing the cyan hue saturation while reducing the vibrance of yellows, for instance.

Feeding

After the operators calibrate the printers to the appropriate color profiles, they begin offset printing.

Air jets automatically push a single sheet of paper into the printers to automate the process. Modern printers have detectors that shut the system down if it registers a paper is too thick, which means two sheets stuck together upon feeding. Once the paper enters the printer, it passes through the printing cylinders to receive ink.

Printing

The ink travels through a sequence of rollers and cylinders before arriving at the paper, and it first starts at the plate cylinder.

Dampening rollers apply water to the non-image parts of the print as the plate cylinder revolves, while the ink rollers apply ink to the image parts of the print. Water is necessary because it is chemically structured to reject ink, allowing for clean separations between colored and non-colored areas on the print.

As the plate cylinder revolves, it transfers only the ink onto the revolving rubber-wrapped blanket cylinder below it. The blanket cylinder is the only inked cylinder that touches the paper. Beneath the paper is an impression cylinder, which presses it up to fuse the ink into place.

The paper then passes through a series of similar cylinders with different colored inks to form the final product.

Drying

Once the paper receives the final coat of ink, the printer deposits it on a stack at the end. The ink is still wet at this point. A machine sprays anti-set-off powder onto the printed sheets, preventing them from sticking to each other or causing ink smudges after printing.

Printer operators then bring printed sheets to a guillotine and trim the papers.

It is easy to feel overwhelmed by offset printing, but it often produces higher-quality prints than other methods. Understanding other printing methods help one decide which is ideal for the given job; digital printing is one of the most popular.

Offset Printing vs. Digital Printing: What’s the Difference?

Experts forecast the printing industry will reach $862 billion by 2024. With how large the printing industry is becoming, it helps to understand the differences between different types of printing methods. Businesses may have internal debates about which is better for their business needs, offset printing vs. digital printing.

Knowing the difference between offset printing vs. digital printing helps decide which is best to achieve company goals.

Quantity

Offset printing is ideal for orders of more than 1,000 copies, such as magazines and newspapers, since reaching that amount is much easier and more efficient. Digital printers work slower compared to offset printers, better suiting smaller orders.

Quality

Printing professionals consider the quality of offset printing to be unmatched. The method allows one to carefully adjust and calibrate each color, producing a vibrant and detailed final product.

It is not to say that digital printing cannot produce high-quality images. Modern digital printers are improving the quality of their outputs, allowing for accurate colors on the material.

Method & Process

The digital printing process is much more straightforward than offset printing. Recall that offset printing requires a prepress step that entails operators preparing the printers—different machines which print only a single color—before printing even begins.

Digital printing allows businesses to jump directly to the printing step. Digital printers either print through inkjet or laser. The printer will squirt tiny ink droplets onto the paper through the inkjet process. The laser method is more complex. It uses a laser light that neutralizes a rotating drum’s surface, attracting electrically charged toner.

The printer then applies heat and pressure onto the paper passing through to fuse the toner directly. This process lets one touch the finished product immediately after printing without worrying about smudging the design.

Turnaround time

Digital printing has a faster turnaround time because it does not require the preparation step common to offset printing methods. It will not need a long wait to touch the final product since it uses a different inking method. Digital printing will still lag offset printing when the orders are much higher.

While it might still take a few days to handle the finished products safely, offset printing produces hundreds of copies quickly, allowing them to dry simultaneously.

Cost

The cost difference depends on the quantity one requires. Orders of less than 1,000 benefit more from digital printing, while those above that amount are ideal for offset printing. The price per sheet drops the higher the volume one orders for offset printing. Hence, it is a matter of one’s budget and quantity requirements.

5 Advantages of Offset Printing

Businesses deciding to use offset printing can enjoy multiple benefits, such as the following

1. High-quality printing

Professionals in the industry know that offset printing quality is distinct and unmatched. Printing operators and clients configure color settings per printer to achieve accurate printing results.

2. Inexpensive printing

Most of what businesses will pay for is setting up the process, such as acquiring the necessary aluminum plates, transferring the designs onto them, and calibrating the specific colors.

Once the printers are set up, it becomes easy to print thousands of copies rapidly. The price per print falls the more prints are ordered. The quality one receives for the number of prints ordered makes offset printing a worthwhile investment.

3. Quick turnaround time

Setting up the printing plates and waiting for the finished products to dry are the only parts of the process that delay the turnaround time. Despite this, offset printing is still relatively faster than digital printing for high-volume jobs.

4. Sustainable

The ink that printers use contributes to what makes the process more sustainable. Certain printing operations use vegetable-oil-based ink to produce more biodegradable packaging for their clients.

Another reason is the aluminum plate of the plate cylinder. It lasts longer because it comes into contact with the soft, rubber blanket cylinder instead of potentially abrasive and coarse printing material such as cardstock or wood.

5. Multiple material options

Printing on multiple materials allows experimentation with different product packaging designs.

Offset printing works for different materials, surfaces, and shapes. For instance, businesses requiring sturdy and well-designed product packaging will find offset printing ideal. The sturdy product packaging will also help respond to trending customer demands, according to the latest packaging statistics, where more are preferring paper and cardboard packaging.

Balance Quality with Cost

Businesses printing thousands of stationary or document copies expect to complete their orders quickly. Food and beverage companies quickly print thousands of new packaging designs, and publishing companies rapidly generate thousands of the latest edition copies. There are several reasons why offset printing is so popular across industries.

Offset printing is a viable option for product packaging needs. If you are unsure how to implement offset printing into your business, it is best to work with printing experts such as Meyers. We offer printing solutions that bring your packaging and printing solutions to life.

Contact us today to learn how we can help you.