What Is Primary Packaging? Understanding the 3 Layers of Product Packaging

Primary packaging is the first layer your customer sees and touches, and it plays a pivotal role in product protection, consumer satisfaction, and brand storytelling. Whether it’s a folding carton for a retail item or pressure sensitive label that delivers both branding and regulatory information, this layer directly shapes how your product is perceived.

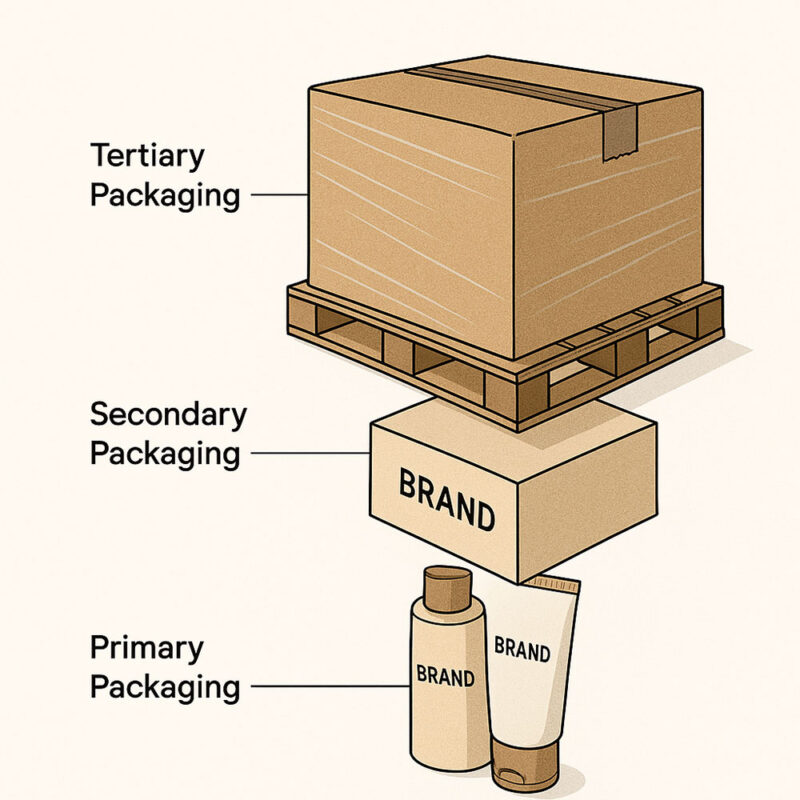

However, to design truly effective packaging for retail or shipping, businesses must also evaluate all types of product packaging, including secondary and tertiary packaging. Together, these layers form a cohesive system that protects product quality, enhances retail appeal, and advances sustainability goals.

Throughout this guide, we’ll break down each layer of product packaging, starting with an in-depth look at how primary packaging, including formats like folding cartons and pressure sensitive labels, supports the functionality, compliance, and consumer journey.

The 3 Essential Layers of Product Packaging

What are the layers of product packaging? Understanding primary, secondary, and tertiary packaging is essential for any brand that ships or displays goods. These three layers guide businesses in selecting materials and packaging designs for both shipping and retail, supporting strong branding and sustainable practices.

1. Tertiary Packaging: The Transit Shield

Examples of Tertiary Packaging

Tertiary packaging, often referred to as bulk or transit packaging, is the outermost layer that protects products during transport from manufacturing facilities to retail destinations or distribution hubs. As a key element of packaging design for shipping, it ensures items arrive safely, are easy to manage logistically, and are clearly labeled.

Key Functions of Tertiary Packaging

- Protection during shipping: It shields products from stacking pressure, handling damage, and environmental exposure, ensuring items arrive safely.

- Logistics efficiency: In addition, it streamlines warehouse storage, loading, and unloading processes, which improves supply chain productivity.

- Brand identification: Moreover, tertiary packaging allows for clear labeling and visual cues that enhance identification throughout distribution systems.

For example, common types of tertiary packaging include stretch-wrapped pallets, bulk shipping containers, and corrugated master cartons that house multiple product units.

To align with modern sustainability standards, many brands are now turning to eco-friendly options for shipping and retail packaging. These include:

- Biodegradable pallet wraps made from compostable materials

- Recyclable corrugated boxes certified by FSC or SFI

- Returnable containers designed for closed-loop distribution systems

2. Secondary Packaging: The Shelf Ambassador

Secondary packaging bridges protection and presentation, seamlessly linking the functionality of outer layers with the visual and branding impact essential for retail success. Specifically, it consolidates individual product units for easier transport and merchandising, while at the same time elevating shelf appeal and supporting effective retail packaging design.

Importantly, this layer is often the first touchpoint for consumers in retail environments, directly influencing purchasing decisions through presentation, messaging, and perceived quality. In addition, it provides essential space for compliance information, barcodes, promotional content, and storytelling, making it a powerful tool for both regulation and brand communication.

Key Functions of Secondary Packaging

- Product grouping: Bundles multiple primary packages for ease of transport and display

- Retail readiness: Creates a polished, shelf-ready appearance

- Brand communication: Offers space for logos, claims, and required product info

- User experience: Makes product handling and merchandising simpler for stores

This layer is especially important when determining how to choose the right product packaging for retail settings, where visual competition is high and packaging often influences consumer trust.

Examples of Secondary Packaging

Some common examples of secondary packaging include:

- Retail-ready boxes for electronic accessories, designed for quick shelf placement

- Folding cartons that contain multiple sachets or pouches, offering both protection and organization

- Display-ready trays for snacks, cosmetics, or over-the-counter health items, which simplify merchandising

- Six-pack carriers for beverages or personal care products, providing convenience for both retailers and consumers

To further support sustainability goals, many brands are opting for eco-friendly options for shipping and retail packaging. These include recyclable folding cartons, plastic-free window cutouts, and minimalist designs that reduce waste without compromising shelf appeal or branding opportunities.

Brand Advantage: Secondary packaging provides valuable communication space to connect with consumers. In fact, research shows that 72% of consumers form their first impression of product quality based on secondary packaging appearance, underscoring how essential this layer is for brand differentiation.

3. Primary Packaging: The Product Guardian

Primary packaging directly encloses your product, preserving its integrity, delivering brand messaging, and shaping the consumer’s first impression. Also known as retail or consumer packaging, this layer has a significant impact on the user experience and stands as one of the most influential types of product packaging in your strategy.

More than just protection, primary packaging shapes how consumers perceive your product on the shelf or at unboxing. It carries critical compliance information, reinforces your branding, and must be designed with both aesthetics and functionality in mind.

Key Functions of Primary Packaging

- Product protection: Maintains product quality, freshness, and safety

- Consumer experience: Influences satisfaction through design, usability, and appearance

- Labeling & compliance: Displays regulatory content, ingredients, usage instructions, and certifications

- Brand identity: Communicates your brand through logos, colors, and messaging

Examples of Primary Packaging

- Food containers like yogurt cups, snack pouches, or salad bowls

- Beverage bottles made of glass, PET, or aluminum

- Cosmetic tubes and pumps for lotions or cleansers

- Electronic boxes with molded inserts or tamper-evident seals

As the layer most often kept or handled by consumers, primary packaging is also central to retail packaging design. It must reflect your brand values while meeting shelf, e-commerce, or direct-to-consumer requirements.

To meet growing environmental expectations, brands are adopting eco-friendly options for shipping and retail packaging at the primary level. These include:

- Mono-material designs (e.g., PET-only containers) that simplify recycling

- Compostable films and pouches for food and personal care items

- Refillable containers for cosmetics or cleaning products

- Lightweight packaging that reduces material use and emissions

Labeling and Certification Considerations

Primary packaging is not only responsible for product safety and visual appeal, but it also plays a key role in regulatory compliance. This layer must include all required industry-specific labeling, and in many cases, align with sustainability certifications and eco-friendly packaging options.

Labeling Requirements by Industry

Primary packaging is often the final interface between your brand and the consumer, and it must communicate essential information clearly and accurately. Regulations vary by industry, but here are the most common labeling requirements:

- Food & Beverage

- Nutrition Facts panel

- Ingredient list and allergen disclosures

- Expiration or “best by” dates

- Country of origin

- Barcode (UPC or EAN)

- Pharmaceuticals & Health Products

- Active/inactive ingredients and dosage instructions

- Warnings, side effects, and contraindications

- Lot number and expiration date

- Compliance with FDA (U.S.) or EMA (EU) regulations

- Tamper-evident features

- Cosmetics & Personal Care

- Ingredient transparency (INCI format)

- Net weight or volume

- Shelf life or “period after opening” symbol

- Product function (e.g., moisturizer, cleanser)

- Responsible party (manufacturer or distributor)

Pressure sensitive labels are ideal for accommodating these details, especially when space is limited or packaging requires flexibility. They can also be manufactured using recyclable, wash-off, or compostable materials, helping brands meet sustainability goals without compromising regulatory accuracy.

Failing to meet labeling standards can result in legal penalties, product recalls, or erosion of consumer trust. Therefore, partnering with a packaging provider experienced in regulatory frameworks and label engineering, like Meyers, helps ensure compliance, functionality, and visual impact from the start.

Strategic Considerations for Effective Product Packaging

Choosing the right product packaging isn’t just about materials, it’s about aligning each layer with business goals, regulations, and customer values. Consider how your primary packaging, secondary packaging, and tertiary packaging support your brand, operations, and environmental strategy.

Best Materials for Sustainable Product Packaging

Consumers today expect responsible packaging choices. Sustainable options include:

- Recycled and recyclable materials

- Biodegradable and compostable alternatives

- Lightweight designs that reduce material usage and shipping costs

Meyers’ sustainable packaging solutions help you balance environmental responsibility with performance requirements, addressing consumer preferences while maintaining product integrity.

Brand Consistency Across Layers

Maintaining visual consistency throughout all packaging layers reinforces brand recognition and perceived value. Consider how your packaging elements work together:

- Consistent color schemes and typography

- Strategic logo placement and sizing

- Cohesive storytelling from outer box to inner container

Operational Efficiency

Well-designed packaging streamlines operations throughout your supply chain:

- Easy assembly and packing processes

- Space-efficient storage and transportation

- Smooth transitions between packaging layers

Packaging Lifecycle and Circularity

Creating truly sustainable packaging requires more than choosing recycled materials. Each layer, from primary packaging to tertiary packaging, should contribute to your brand’s transition to a circular packaging system. That means designing for recyclability, reusability, and incorporating eco-friendly options for shipping and retail packaging.

Primary Packaging

As the most visible and consumer-facing layer, primary packaging plays a pivotal role in circularity:

- Recyclability: Use mono-materials (like PET or HDPE) where possible to ensure clean recycling streams.

- Refill & Reuse Models: In cosmetics and personal care, refillable containers are gaining popularity for reducing waste and encouraging brand loyalty.

- Compostable Options: Certain food-grade films and bioplastics are designed for industrial composting, depending on the product category.

Secondary Packaging

Often discarded quickly after purchase, this layer should be optimized for:

- Curbside Recyclability: Paperboard boxes and display cartons should be easily recyclable.

- Design for Disassembly: Avoid plastic windows or mixed-material glues that hinder recyclability.

- Minimalism: Use just enough material to achieve protection and branding goals, minimizing unnecessary waste with minimal packaging design.

Tertiary Packaging

Used primarily for bulk shipping and logistics, tertiary packaging offers major opportunities for reuse and recovery:

- Pallet Wraps: Choose recyclable or biodegradable stretch films when possible.

- Corrugated Boxes: Source FSC- or SFI-certified boxes and design them for maximum reusability within internal supply chains.

- Closed-Loop Systems: For B2B models, consider returnable shipping containers or bins that cycle between distribution centers and manufacturers.

Implementing recovery, reuse, and recyclability strategies across all packaging layers supports your brand’s transition to a circular packaging system, one that minimizes environmental impact while delivering functional, high-performing packaging.

Transform Your Custom Packaging Solutions With Meyers

A sustainable packaging strategy goes beyond just picking recycled materials. Each layer, from primary packaging to tertiary packaging, should support your brand’s transition to a circular packaging system. This includes designing with recyclability, reusability, and eco-friendly options for shipping and retail packaging in mind.

Contact Meyers today to discuss how our custom packaging solutions can enhance your product experience while supporting your business goals. Our team of experts is ready to bring your packaging vision to life with the right balance of quality, functionality, and brand impact.