How to Choose the Best Food and Beverage Packaging Materials (With Sustainability and Performance in Mind)

Product packaging is a strategic asset in the food and beverage industry. The materials you choose affect product protection, shelf life, regulatory compliance, and how your brand is perceived at retail. From preserving freshness to standing out on crowded shelves, packaging decisions directly influence both performance and purchase decisions.

Meyers is a U.S.-based packaging manufacturer supporting food and beverage brands with carton packaging, pressure sensitive labels, and sustainable packaging solutions designed for real-world production and distribution environments. With decades of experience across regulated and high-volume packaging applications, we help brands select materials that balance durability, sustainability, and visual impact.

In this guide, we break down the key factors to consider when choosing food and beverage packaging materials, including durability, aesthetics, sustainability, and brand alignment, so you can make informed decisions that support both your product and your business goals.

Quick Answer: What Are the Best Packaging Materials for Food and Beverages?

The best food and beverage packaging materials balance product protection, safety, sustainability, and shelf appeal. Common options include paperboard folding cartons for dry foods, aluminum and glass for beverages, compostable or biodegradable materials for short shelf-life products, and pressure sensitive labels designed to withstand moisture, refrigeration, and handling.

How to Choose the Best Food and Beverage Packaging

When deciding on the most suitable packaging materials for food and beverage products, businesses need to consider a variety of factors to make well-informed choices.

How Durable Do Food and Beverage Packaging Materials Need to Be?

Assess the robustness of materials concerning factors like moisture, temperature variations, and physical stress during transportation. For food, packaging materials like vacuum-sealed pouches or compostable trays can ensure freshness and prevent spoilage. In contrast, beverages benefit from durable options such as PCR plastic bottles or aluminum cans, protecting them from external elements.

How Does Packaging Design Impact Food and Beverage Brand Appeal?

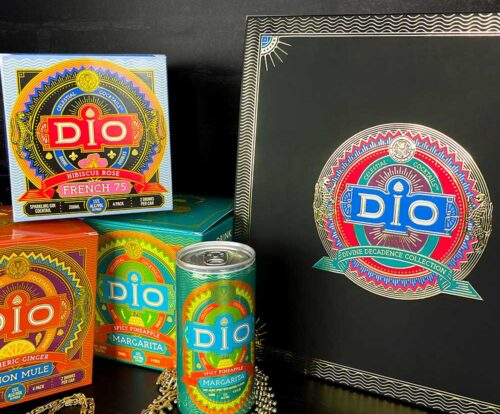

Recognize the significance of visual elements that convey your brand identity effectively. Striking a balance between visual attractiveness and practicality is crucial. One of the best food packaging materials used today is stand-up pouches with vibrant graphics that can enhance shelf appeal, while sleek and innovative designs for beverage cans contribute to a modern and appealing presentation.

How Can Brands Make Beverage Packaging More Sustainable?

Evaluate the environmental impact of packaging materials for both food and beverage items. Opt for options that are renewable, biodegradable, or recyclable. For instance, consider food packaging made from plant-based materials such as bioplastics, or recyclable glass or aluminum for beverages. These align your brand with eco-conscious consumer preferences and demonstrate a commitment to environmental responsibility.

How Do Brands Balance Sustainability and Performance in Packaging?

Prioritize sustainability without compromising functionality for food and drink packaging materials. Optimize designs to minimize material usage while maintaining structural integrity. For example, choosing a minimalist and eco-friendly cardboard box for snack packaging or adopting lightweight, eco-conscious labels for beverage bottles achieves that desired balance.

How Should Packaging Materials Reflect Brand Values?

Ensure that your chosen materials align with your brand’s values and resonate with your target audience. The packaging should tell a compelling story about your commitment to quality, sustainability, and overall brand integrity. Consider using bio-based materials for food containers and incorporating recycled content in beverage packaging to showcase your dedication to environmental responsibility.

6 Best Food and Beverage Packaging Materials to Consider

Choosing the right packaging materials is pivotal for preserving the quality of your food and beverage products. The selection process involves weighing factors such as sustainability, functionality, and visual appeal. Here are five top-notch materials suitable for the food and beverage industry.

1. Paperboard

Paperboard and folding cartons are widely used for dry foods and secondary beverage packaging due to their print quality, recyclability, and lightweight structure.

Paperboard is a versatile packaging material typically produced from recycled fibers or post-consumer waste, making it a strong option for brands focused on sustainability and circular packaging systems. Its balance of strength and flexibility allows it to protect products while remaining easy to transport, store, and recycle.

Folding cartons are especially common in the food and beverage industry for items such as dry foods, multipacks, and secondary beverage packaging. They offer excellent printability, allowing brands to showcase high-quality graphics, regulatory information, and sustainability messaging directly on the package. This makes sustainable folding cartons well suited for retail environments where shelf impact and brand clarity matter.

For beverage applications, paperboard cartons with plant-based or water-based barrier coatings provide an eco-friendly alternative to plastic bottles in certain use cases. These cartons are lightweight, often contain high levels of renewable content, and can support recycling streams when designed correctly.

Overall, paperboard packaging supports a wide range of food and beverage applications by combining strong visual presentation, efficient logistics, and sustainability advantages. When paired with the right coatings, structural design, and printing methods, folding cartons remain one of the most adaptable and widely used packaging formats in the industry.

2. Pressure-Sensitive Labels

Pressure sensitive labels are widely used for food and beverage products packaged in bottles, cans, jars, and rigid containers where durability, compliance, and visual consistency are essential.

Pressure sensitive labels adhere to containers using an adhesive backing and do not require heat or water for application. This makes them highly adaptable across packaging formats, including glass, aluminum, and plastic containers commonly used in food and beverage packaging.

These labels are designed to perform in demanding environments such as refrigeration, condensation, moisture exposure, and high-speed production lines. Because of this reliability, pressure sensitive labels are frequently used for beverages, sauces, condiments, supplements, and packaged foods that require consistent adhesion and legibility throughout distribution and retail handling.

From a branding and compliance perspective, pressure sensitive labels offer excellent print quality and layout flexibility. They accommodate nutritional panels, ingredient lists, barcodes, certifications, and recycling information while supporting premium finishes and strong shelf presence.

Eco-friendly pressure sensitive labels can also support sustainability goals through recyclable label constructions, wash-off adhesives, and materials designed to align with container recycling streams, making them a practical solution for brands balancing performance, compliance, and environmental considerations.

3. Biodegradable materials

Biodegradable packaging materials are best suited for food products with shorter shelf lives or controlled disposal environments where composting or biodegradation is more likely.

Biodegradable packaging materials have become an integral component in reshaping the industry’s impact on the planet. These resonate with the overarching goals of creating a circular economy, one where packaging materials harmonize with the environment rather than burden it.

A common type of biodegradable packaging, bioplastics, is a polymer derived from biological sources as opposed to conventional plastics that rely on fossil fuels. These materials can be either biobased, biodegradable, or a combination of both.

Companies such as Coca-Cola are adopting these materials for their products. Their PlantBottle technology incorporates sugarcane-derived polyethylene in PET bottles. This move has contributed to the company’s carbon footprint reduction.

4. Compostable materials

Compostable packaging works well for prepared foods, produce, and foodservice applications where access to composting infrastructure exists.

Packaging made from compostable materials, such as bagasse, bamboo, molded pulp, or mushroom mycelium, provides an environmentally friendly alternative to conventional packaging. These materials break down naturally and can be composted alongside organic waste.

In the food sector, food containers made from compostable paper are sturdy and practical while reducing the environmental impact associated with conventional plastic containers. Similarly, compostable cardboard trays are employed for packaging fruits, vegetables, and other perishable items, providing a sustainable solution for short shelf-life products.

5. Glass

Glass packaging is ideal for beverages and sauces that require strong barrier protection, premium presentation, and long shelf life.

Glass is a timeless packaging option for both food and beverages. It’s an ideal material for eco-friendly beverage packaging due to its recyclability without loss of quality and durability. Glass bottles are suitable for products requiring UV protection, such as craft beers. Glass jars for sauces or condiments in the food industry convey a premium image and preserve the product’s taste.

Glass packaging is also easy to clean and transportable, making it appealing to consumers. More importantly, glass packaging can be discarded with minimal negative environmental impact. It contributes to a circular economy by facilitating endless recycling without compromising the integrity of the material.

6. Metal

Aluminum packaging is commonly used for beverages and shelf-stable foods that require strong protection against light, oxygen, and moisture.

Metal packaging materials are versatile and suitable for both food and beverages. Aluminum, in particular, is known for its high recyclability, energy efficiency, and versatility without compromising quality. It contributes to a closed-loop recycling system, while its lightweight nature reduces transportation-related emissions.

Aluminum cans for beverages offer protection against light, moisture, and oxygen, ensuring the product’s freshness. For food packaging materials, foil pouches made from aluminum are typically used for snacks or coffee.

Savoring Success: Package Your Food and Beverages Right

From eye-catching designs to strategic selection of sustainable materials, choosing the best packaging material for food and beverage products is no longer merely about how to store products for consumption.

The right packaging also helps companies establish their brand and values. Remember, your choice of packaging material is an opportunity to convey your brand’s commitment to excellence. Whether it’s the earthy charm of biodegradable packaging or the sleek allure of more premium materials, each material tells a unique story.

Elevate your food and beverage packaging to new heights. Meyers is a U.S.-based packaging manufacturer supporting food and beverage brands with folding carton packaging, pressure sensitive labels, and sustainable packaging solutions designed for real-world production and distribution environments.

Food & Beverage Packaging FAQs

Food-safe packaging materials include paperboard cartons with approved coatings, glass, aluminum, and certified biodegradable or compostable materials designed for food contact.

Not always. While some sustainable materials have higher unit costs, lightweight designs, right-sizing, and recyclable materials can reduce shipping and compliance costs over time.

Refrigerated beverages typically require moisture-resistant containers and pressure sensitive labels designed to withstand condensation, cold temperatures, and handling.

Last Updated on February 2, 2026