Mycelium Packaging Applications: How Mushrooms Are Transforming The Packaging Market

Each day, consumers are growing more concerned over the use of environmentally unsustainable materials such as plastics and polystyrene (commonly known as Styrofoam) in everyday packaging. Polystyrene in particular not only has adverse effects on the environment but can also harm people’s health. As such, sustainable product packaging has grown more popular over the years as more businesses share this concern and adopt a greener, healthier approach.

Rather than depending on materials that make use of limited fossil fuel resources, natural packaging solutions provide a great alternative. Among these is mushroom-based packaging made from mycelium materials. But as the packaging industry adopts these materials into their operations, not many are familiar with what mycelium packaging can do and the benefits it provides.

What is Mycelium Packaging?

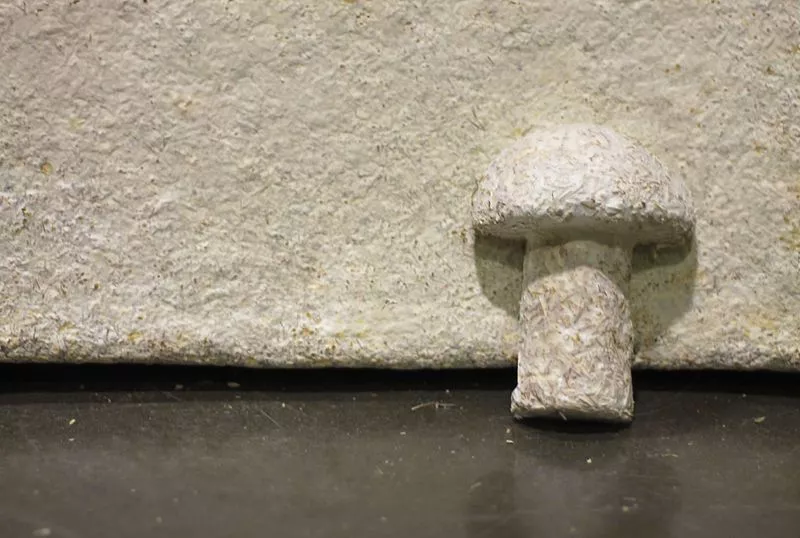

Mycelium comes from the root network of a fungus, which is the part of the mushroom that is typically underground. It branches out and interconnects as a fine thread that can grow into any shape. As such, it has no size limit on how large it can grow. For instance, the Armillaria network spans over 2,400 acres.

When used in packaging, mycelium can replace commonly-used materials such as polystyrene while improving the overall product and manufacturing process. It is lightweight, durable, and flexible by design. As such, it has become a more cost-effective packaging solution than other sources.

How is Mycelium Packaging Made?

To start manufacturing mycelium packaging, the fungus is placed to grow around a collection of agricultural scraps such as husks or corn stalks. It is then left to grow for a few days until it fully envelops and binds the waste together. Once it forms a solid shape, manufacturers cut off pieces of it to place in a drying chamber.

The drying process prevents the mycelium from growing any further. Once it is ready, it is molded into any desired shape or form to fit the required packaging design.

Advantages of Mycelium Packaging

Switching to mycelium packaging can benefit your brand and the environment in various ways. For instance, mushroom packaging is an entirely biodegradable and renewable material that can benefit the environment. Even when discarded as litter, nature can naturally recycle these products over time, leading to little to no waste. It also serves as a natural compost to help plant more trees and other greenery.

Using mycelium in your product packaging can also be considered more inexpensive than polystyrene foam and other similar plastics. Since mycelium can be molded into any shape more easily, your business can reduce energy consumption while producing it in bulk. It can also take up less space, allowing you to transport more with less cost.

Mycelium Packaging Applications

Considering its flexibility, mycelium-based packaging can be applied to different forms of packaging solutions today. Since the material can be easily molded into any desired shape or form, it can fit your packaging design needs more accurately.

Moreover, not much waste is produced when manufacturing mushroom packaging. Dell, for example, uses natural fungi for their cushion packaging. This sustainable packaging alternative is used for shipping heavy products such as servers. The mushroom cushions only take five to 10 days to grow. Moreover, all the required energy comes from the mushrooms’ carbohydrates, which need no added fuel.

Another way of using mushroom packaging is by introducing other biodegradable materials into the mix to create different products. A few include imitation styrofoam which can be used to package goods and keep them safe during transit. Compared to traditional packaging materials, it is also much simpler to recycle and compost.

Utilizing mycelium-based biocomposite foam supports the commitment to use renewable materials for greater sustainability. When these types of materials are developed to be more cost-effective, it could reduce the use of non-biodegradable petroleum-derived synthetic waste materials that contribute to pollution. They can also potentially make persistent oil-based plastic materials obsolete and transform the way the packaging industry impacts the environment.

The agricultural waste from growing mycelium biocomposite material could also serve as added income to farmers who use these as raw materials instead of incinerating them. The raw materials used to grow mycelium can be any agricultural by-products or feedstock material that is locally available. This makes it suitable for manufacturing biocomposite foam from anywhere in the world, with minimal logistics and transportation.

As more consumers become vocal on local and sustainable products, using mycelium biocomposite packaging materials can allow brands to tap into these consumers’ values while reducing their negative environmental impact.

Merge and Transform Packaging with Mushrooms

The effects of global problems such as climate change have become more apparent in recent years. As natural resources are growing scarce, consumers and businesses are becoming more concerned over the matter. As such, packaging industries now have to turn towards sustainable alternatives to manage the situation.

While using biodegradable materials such as paper is common, mycelium-based packaging also has the potential to transform the industry. It is a worthy alternative that is flexible, lightweight, and can be advantageous to your brand and the environment.

Learn more on how to optimize your product packaging materials selection. Reach out to the packaging solutions experts at Meyers.