Eco-Friendly Inks for Packaging: Types, Benefits, Trends

The use of eco-friendly inks for consumer product packaging is on the rise. In response to rising environmental concerns and shifting consumer preferences, the packaging industry is undergoing a significant shift towards sustainability.

Consumers are increasingly influenced by environmental considerations, prompting brands to prioritize more eco-friendly packaging options. Simultaneously, regulatory pressures and industry standards are driving the adoption of eco-friendly practices, compelling businesses to seek out sustainable alternatives.

A notable trend in line with this is the increasing adoption of eco-friendly inks for packaging and printing, which offer a more sustainable and responsible alternative to traditional petroleum-based inks.

Advancements in research and development have led to the formulation of eco-friendly inks that deliver comparable performance and quality to conventional inks. Printers and packaging manufacturers now have a diverse range of options available. This shift towards eco-friendly inks signifies a broader commitment to sustainability in the packaging industry and paves the way for a greener future.

In this article, learn the types, benefits, and emerging trends of eco-friendly inks shaping the landscape of sustainable packaging. From reducing environmental impact to enhancing print quality and consumer perception, eco-friendly inks are ushering in a new era of responsible packaging practices.

Jump to a Section:

- Benefits of Using Eco-Friendly Inks for Packaging

- Main Types of Eco-Friendly Inks

- Emerging Trends in Eco-Friendly Inks for Packaging

What are Eco-Friendly Inks?

Eco-friendly inks are printing inks formulated with renewable and sustainable resources designed to minimize environmental impact throughout their lifecycle. Unlike traditional petroleum-based inks, eco-friendly inks are made from ingredients such as water, soybean oil, and plant-derived resins.

What makes these inks eco-friendly is their reduced reliance on non-renewable resources and their lower emission of volatile organic compounds (VOCs), which contribute to air pollution and environmental degradation. Prioritizing renewable materials and minimizing toxic components make eco-friendly inks a more environmentally responsible option for printing and packaging applications.

5 Benefits of Using Eco-Friendly Inks for Packaging

The adoption of eco-friendly inks for printing and packaging offers several benefits, from environmental sustainability to improved print quality and consumer perception. Here are some of the key advantages.

1. Lower environmental footprint

Eco-friendly inks are formulated with renewable and sustainable resources. This helps minimize the consumption of non-renewable fossil fuels and reduce carbon emissions. Through the use of eco-friendly ink alternatives such as water-based, soy-based, and UV-curable inks, brands and packaging manufacturers can significantly lower their environmental footprint and contribute to conservation efforts.

2. Less health and safety risks

Eco-friendly inks are typically free from toxic chemicals and harmful substances commonly found in traditional petroleum-based inks, reducing the risk of health hazards for workers and consumers. By eliminating or minimizing the emission of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs), eco-friendly inks promote safer working environments and healthier indoor air quality.

3. Excellent print quality

A possible misconception is that eco-friendly inks compromise performance. On the contrary, many eco-friendly ink formulations offer comparable or even superior print quality to conventional ink.

Water-based inks, for example, are known for their vibrant colors, fast drying times, and excellent adhesion to various substrates, making them suitable for high-quality packaging applications. Similarly, UV inks offer enhanced durability, scratch resistance, and color saturation, ensuring long-lasting and visually appealing graphics on packaging materials.

4. Regulatory compliance

The use of eco-friendly inks aligns with regulatory requirements and industry standards aimed at reducing environmental pollution and promoting sustainable practices.

Regulations and certifications include the Forest Stewardship Council (FSC) Certification, compostable standards such as the Biodegradable Products Institute (BPI) certification, and internationally recognized standards like Environmental Management System (EMS) or ISO 14001, among others. The adoption of eco-friendly ink solutions can help brands mitigate the risk of fines, penalties, and reputational damage associated with non-compliance.

5. Positive consumer perception and brand image

Consumers are placing greater importance on sustainability and eco-friendliness when making purchasing decisions. Packaging materials and products labeled with eco-friendly inks convey a commitment to environmental stewardship and resonate positively with these consumers. This, in turn, boosts a brand’s reputation, builds trust with its consumers, and differentiates the brand in a competitive market.

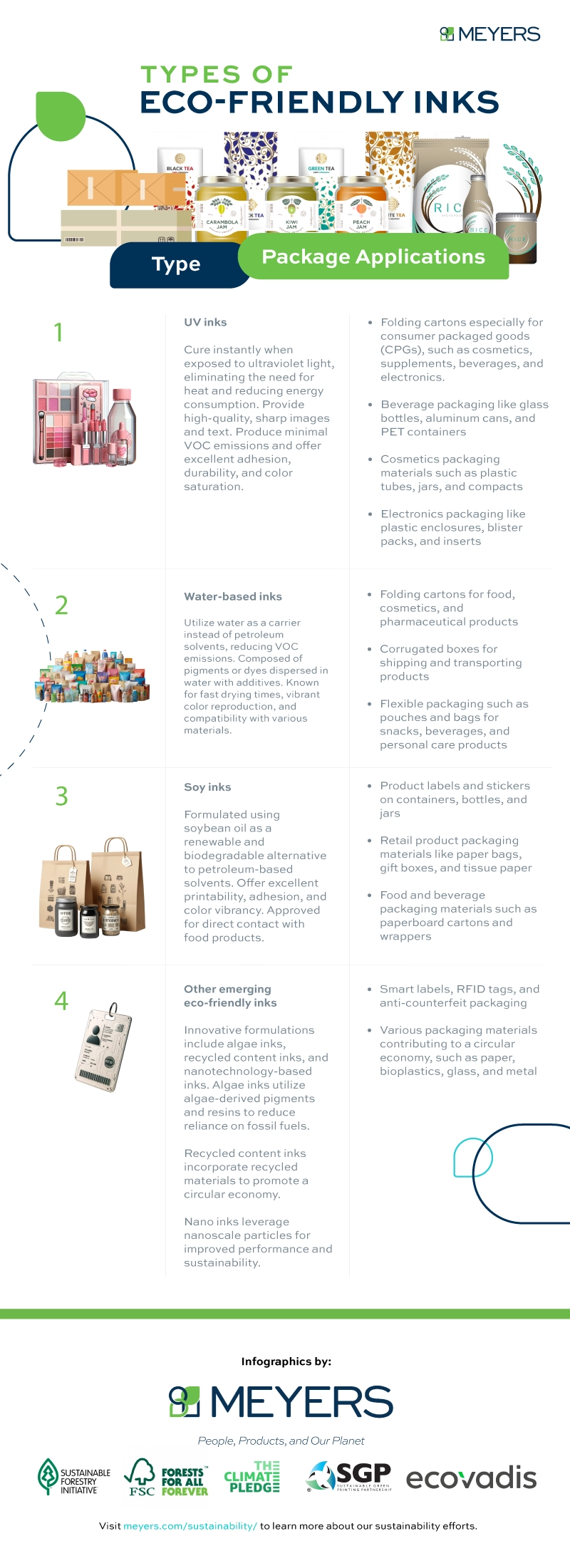

The Main Types of Eco-Friendly Inks

Eco-friendly inks encompass a variety of formulations that prioritize environmental responsibility. Each type of eco-friendly ink offers unique characteristics and benefits, catering to different printing requirements and substrate materials. Here are some of the prominent types of eco-friendly inks widely used in the packaging industry.

1. Water-based inks

Water-based inks utilize water as a carrier instead of petroleum solvents, significantly reducing the emission of VOCs during the printing process. These inks are composed of pigments or dyes dispersed in water, along with additives to enhance color intensity, drying time, and adhesion. Water-based inks are known for their fast drying times, vibrant color reproduction, and compatibility with various packaging materials.

For instance, they are commonly used for printing on folding cartons used for packaging consumer goods such as food, cosmetics, and pharmaceutical products. Meanwhile, water-based inks on corrugated boxes provide excellent adhesion and color vibrancy on corrugated cardboard boxes used for shipping and transporting products. These inks are also increasingly being adopted for printing on flexible packaging materials such as pouches and bags used for snacks, beverages, and personal care products.

2. Soy inks

Soy-based inks are formulated using soybean oil as a renewable and biodegradable ink alternative to petroleum-based solvents. By replacing a portion of the traditional ink components with soybean oil, these inks reduce the emission of VOCs and minimize environmental impact. Soy inks offer excellent printability, adhesion, and color vibrancy, making them suitable for various printing applications, including product packaging.

For example, soy inks are commonly used for printing product labels and stickers applied to containers, bottles, and jars. The ink is also suitable for retail product packaging materials such as paper bags, gift boxes, and tissue paper, enhancing the eco-friendly appeal of the packaging.

Soy inks are also approved for direct contact with food products, making them suitable for printing on food and beverage packaging materials such as paperboard cartons and wrappers.

3. UV inks

UV inks or UV-curable inks are a technologically advanced category of eco-friendly inks that cure instantly when exposed to ultraviolet light. This curing process eliminates the need for heat and significantly reduces energy consumption during printing. UV inks produce minimal VOC emissions and are free from hazardous air pollutants, contributing to improved air quality and worker safety. These inks offer excellent adhesion, durability, and color saturation, making them ideal for high-quality packaging applications.

Thus, UV inks are widely used for printing on beverage packaging, such as glass bottles, aluminum cans, and PET containers, providing vibrant graphics and brand messaging. For cosmetics packaging, they are typically used on materials such as plastic tubes, jars, and compacts, offering scratch-resistant and waterproof properties. UV inks are also ideal for printing on electronics packaging materials such as plastic enclosures, blister packs, and inserts, ensuring long-lasting and durable graphics.

4. Other emerging eco-friendly inks

Beyond the prominently used types, there are other innovative formulations of eco-friendly inks being adopted for their sustainability credentials. These include algae inks, which utilize algae-derived pigments and resins as key components. These have the potential to reduce reliance on fossil fuels and mitigate environmental impact by using abundant and sustainable algae biomass.

Another example is recycled content inks, which are formulated using recycled materials sourced from post-consumer or post-industrial waste streams. These inks often incorporate recycled pigments, solvents, and other components, reducing the demand for virgin materials and diverting waste from landfills. Closing the loop on material utilization this way contributes to a circular economy and promotes resource conservation.

Meanwhile, nanotechnology-based inks or nano-inks are often used on high-tech packaging materials such as smart labels, RFID tags, and anti-counterfeit packaging to enhance functionality and security. These inks leverage nanoscale particles and structures to improve ink performance and sustainability. These nanoparticles are often incorporated for better color saturation, adhesion, and durability, reducing the need for excessive ink consumption and minimizing environmental impact.

6 Emerging Trends in Eco-Friendly Inks for Packaging

The landscape of eco-friendly inks is continuously evolving, driven by innovation, market demand, and sustainability imperatives. Here are some emerging trends shaping the future of eco-friendly inks in the packaging industry.

1. Sustainable sourcing and supply chains

There is an increasing focus on sourcing raw materials for eco-friendly inks from sustainable and renewable sources. For example, manufacturers are sourcing plant-based oils for soy-based inks from responsibly managed farms, ensuring minimal environmental impact and promoting biodiversity.

Additionally, companies are implementing transparent and traceable supply chains to provide visibility into the origin and production process of eco-friendly inks. This allows brands and consumers to make informed decisions about the environmental and ethical credentials of the products they purchase.

Sustainable sourcing and supply chains are evident in different sectors. To promote transparency and ethical production, brands are using eco-friendly inks sourced from responsibly managed forests for printing on food packaging, such as paperboard cartons and wrappers, as well as beauty packaging for cosmetics and personal care products.

2. Advanced ink formulations and performance enhancements

Innovation in ink technology is driving advancements in the performance and functionality of eco-friendly inks. Manufacturers are developing formulations that offer improved color accuracy, print durability, and substrate compatibility while minimizing environmental harm.

For example, water-based inks are being enhanced with additives to improve adhesion on a wider range of substrates, including non-porous materials such as plastics and metal foils. Similarly, UV inks are being formulated to achieve faster curing times and higher scratch resistance, ensuring durability and longevity in packaging applications.

Packaging applications benefiting from advanced formulations and performance enhancements include beverage packaging, where UV inks with enhanced adhesion properties are used for printing on beverage cans and bottles. These provide vibrant graphics and brand messaging that withstand handling and transportation.

Moreover, water-based inks with improved printability and color vibrancy are used for pharmaceutical packaging, such as blister packs and labels, ensuring readability and compliance with regulatory requirements.

3. Customization and personalization

Eco-friendly inks offer versatility and flexibility in color matching, special effects, and variable data printing, enabling brands to create unique or personalized packaging experiences for consumers. Digital printing technologies, in particular, are driving innovation in customization and personalization capabilities.

E-commerce brands can use eco-friendly inks in combination with digital printing techniques to create personalized packaging designs tailored to individual consumer preferences. This allows for on-demand printing of packaging materials with variable text, images, and graphics.

These can feature personalized messages, branding elements, and product recommendations. Eco-friendly inks can also be utilized for printing limited edition packaging designs with unique colors, patterns, and finishes, creating collectible items that appeal to niche markets and brand enthusiasts.

4. Circular economy initiatives

In the packaging industry, the circular economy concept is driving efforts to minimize waste and maximize resource efficiency. Eco-friendly inks play a crucial role in supporting circular economy initiatives by enabling the recyclability and compostability of packaging materials.

Water-based inks with biodegradable properties are used for printing on compostable packaging materials made from plant-based bioplastics. This ensures that the entire packaging solution, including the ink, can be safely composted after use, reducing waste and supporting closed-loop recycling systems.

Brands can adopt eco-friendly inks and compostable packaging materials for products such as snacks, coffee, and fresh produce, providing consumers with eco-friendly packaging options that can be composted at home or in industrial facilities. Eco-friendly inks also enable the recyclability of printed packaging materials, allowing manufacturers to recover and reuse valuable resources in the production of new packaging items.

5. Carbon-neutral ink formulations

With growing concerns about climate change, there is now an emphasis on reducing carbon emissions associated with ink production and usage. Carbon-neutral ink formulations aim to offset the carbon footprint of ink manufacturing and printing processes through various mechanisms, such as carbon offset projects or investments in renewable energy initiatives.

Ink manufacturers may partner with carbon offset organizations to fund projects that sequester or reduce carbon emissions, such as reforestation efforts or renewable energy installations. By offsetting the carbon emissions generated throughout the lifecycle of the ink, brands can offer carbon-neutral packaging solutions that align with sustainability goals and consumer preferences.

For example, packaging labeled with carbon-neutral ink certifications assures eco-conscious consumers that their purchasing decisions support positive environmental outcomes.

6. Smart ink technologies

Advancements in ink technology are enabling the development of smart ink formulations with enhanced functionality and interactivity. Smart inks incorporate features such as temperature-sensitive, light-reactive, and conductive properties, offering innovative solutions for packaging design and consumer engagement.

Temperature-sensitive inks can change color or reveal hidden messages in response to temperature changes, providing an interactive and engaging experience for consumers. Light-reactive inks can fluoresce or glow under ultraviolet light, adding visual interest and enhancing brand visibility in retail environments. Smart inks with covert features, such as invisible or UV-visible markings, can also be used to authenticate products and protect against counterfeiting, ensuring product integrity and safety.

Recently, a water-based conductive ink has emerged specifically designed for flexible electronic circuits. This ink avoids the use of conventional organic solvents known for their harmful environmental effects, eliminates polluting materials, and simplifies recycling processes.

The technology is suitable for recyclable smart packaging with integrated sensors for perishable food storage monitoring. It enables real-time temperature monitoring for quality assurance and can have future applications to monitor other factors like pressure, humidity, and location.

The ink also aims to revolutionize flexible electronic circuit production by prioritizing sustainability and ease of recycling. It doesn’t require refrigeration, making storage easier while reducing ecological footprints and maintenance costs. Such innovations underscore the fusion of technology and environmental responsibility, paving the way for sustainable electronic solutions.

Ink the Future: Setting a Sustainable Course for Packaging

Beyond mere pigments on paper, eco-friendly inks signify a commitment to environmental stewardship, resonating with consumers who prioritize eco-conscious choices. As brands seek to align with shifting consumer values and regulatory mandates, eco-friendly inks emerge as a reflection of responsible packaging practices, offering a pathway toward a greener future.

Yet, the journey toward sustainability is not static but rather a continuous evolution marked by emerging trends and transformative technologies. The landscape of eco-friendly inks is ripe with opportunities for brands to differentiate themselves and make meaningful environmental contributions.

Collaboration and innovation are key drivers of progress. Meyers is committed to being a trusted sustainable packaging manufacturer for brands aiming to navigate the complexities of eco-friendly packaging solutions. Contact the team of experts to learn more about how we can support your brand’s sustainability goals, one ink at a time.