What Is Product Packaging? An In-Depth Guide for Businesses

Effective product packaging can leave a lasting impression on consumers, influencing sales and brand perception. Take, for instance, Martinelli’s juice bottle, which gained viral popularity on TikTok for its unique design that emits a sound resembling an apple bite. This innovative packaging design boosted Martinelli’s product to household brand name status.

Product packaging plays a pivotal role in the success of businesses across various industries. It goes beyond a mere container and becomes a powerful tool to attract customers, convey brand identity, and enhance the overall customer experience.

This comprehensive guide explores product packaging, from type and material selection to design strategies and trends. Read on and learn how to leverage these in your overall packaging strategy.

Jump to a Section:

- What is Product Packaging?

- Why is Product Packaging Important?

- 3 Main Levels of Product Packaging

- 5 Types of Product Packaging

- 5 Primary Types of Printing for Packaging

- Product Packaging Design Process: 5 Steps

- 5 Product Packaging Trends to Know

- Top Product Packaging FAQs Answered

What is Product Packaging?

Product packaging is the physical materials and design elements used to enclose and present a product. It encompasses the box, container, or wrapping that protects during transportation, storage, and display. Additionally, packaging serves as a communication tool and a brand representation.

Product packaging undergoes a series of design, manufacturing, and printing processes. Ideally, packaging should be visually appealing, aligned with the brand’s identity, and simultaneously functional and practical. Durability, sustainability, and cost-effectiveness are carefully considered during the packaging development.

To learn more about product packaging in different industries, explore the following guides:

- The Complete Guide to Ecommerce Packaging

- Understanding Cosmetics Packaging: A Comprehensive Guide

- Creative Retail Packaging Ideas, Examples, and Strategies

Why is Product Packaging Important?

Product packaging done well brings several essential benefits to a business. It can even affect consumer behavior if one learns to leverage its potential.

1. Protecting the product

Packaging is a protective barrier, safeguarding the product from damage during shipping, handling, and storage. It ensures that the product reaches the consumer in pristine condition, enhancing customer satisfaction and reducing returns.

2. Attracting customers

Packaging is the first point of contact between a product and its potential buyers. Eye-catching and visually appealing packaging can grab attention and entice customers to explore further.

3. Communicating brand identity

Packaging can be an opportunity to convey a brand’s personality, values, and story. Thoughtfully designed packaging establishes a company’s unique identity, connecting with customers and fostering brand loyalty.

4. Enhancing consumer experience

Well-designed packaging can elevate the product. It can provide convenient functionality, such as easy opening and resealing while delivering additional value through informative labels, usage instructions, or promotional materials.

While often overlooked, packaging is a crucial element across all industries. Learn more with the following articles:

- 6 Ways to Use Product Packaging as a Marketing Tool

- Understanding the Role of Packaging in Supply Chain Management

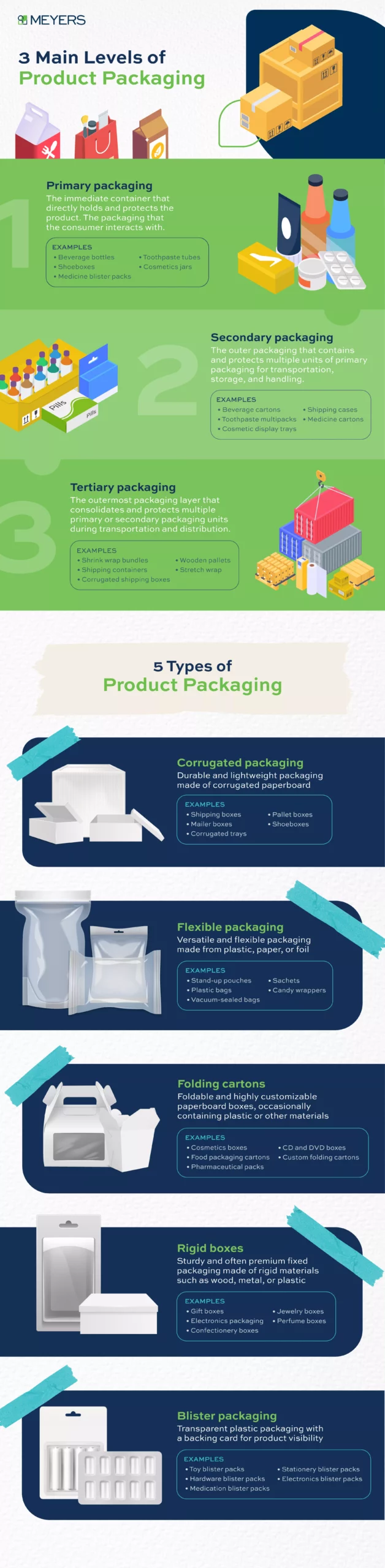

3 Main Levels of Product Packaging

Product packaging consists of three primary levels that indicate the number of layers a product has.

1. Primary packaging

The primary level is the immediate container directly containing the product, and it is the packaging that consumers interact with during purchase and use. Due to its direct consumer interaction, businesses often prioritize the aesthetics and utility of the primary packaging. For instance, a milk company may utilize a glass bottle as its primary packaging.

2. Secondary packaging

Secondary packaging is the outer packaging that holds and protects multiple units of primary packaging. It provides another layer of containment and security, particularly for transportation or storage.

While the brand may give secondary packaging design less priority, it’s worth noting that products typically purchased in bulk, such as fast-moving consumer goods, can still emphasize packaging aesthetics.

Using the above example: loose milk bottles would be difficult to store or move in bulk. A milk business would use wooden or cardboard cartons or trays to efficiently secure many individual milk bottles.

3. Tertiary packaging

Tertiary packaging represents the outermost layer of packaging. It protects multiple units of secondary or primary packaging during distribution. Typically, this level is the least concerned with the design and most concerned with safety and space efficiency.

Open-top milk bottle cartons may suffer in long-distance journeys. The milk company may secure the cartons to wooden pallets with some stretch wrap to minimize breakage.

5 Types of Product Packaging

These standard options offer diverse solutions for many different product categories.

1. Corrugated packaging

Corrugated packaging is made from corrugated paperboard. It consists of a fluted layer sandwiched between liner boards. Its construction and materials make it less expensive than alternatives while remaining extremely sturdy and lightweight. For example:

- Shipping boxes

- Corrugated trays

- Shoeboxes

2. Flexible packaging

Flexible packaging uses malleable materials such as plastic, foil, and paper to wrap a product. They’re lightweight but capable of sealing a product completely, so they’re helpful for sensitive products. Some flexible packaging examples include:

- Plastic bags

- Sachets

- Candy wrappers

3. Folding cartons

Folding cartons are paperboard boxes that you can tuck into a compact form and reassemble. Various consumer goods use folding cartons for their balance of strength and flexibility. They may include other materials, such as plastic, to add visibility or aesthetic flare. Some examples are:

- Food packaging cartons

- Pharmaceutical packs

- Custom folding cartons

4. Rigid boxes

Rigid boxes are sturdy and durable cardboard, wood, or metal packages. They offer high protection and structural integrity, ideal for luxury or delicate items. However, they usually use more materials and are more complicated to transport, making them more expensive. Rigid box product packaging examples include:

- Gift boxes

- Electronics packaging

- Jewelry boxes

5. Blister packs

Blister packs are transparent plastic packaging that securely encloses and displays products. They consist of a formed plastic cavity, known as the blister, which holds the item, along with a backing card that provides structure and product information.

Blister packs are commonly employed by companies selling small consumer goods to enhance visibility and ensure tamper resistance. Some common examples are:

- Toy blister packs

- Medication blister packs

- Hardware blister packs

5 Primary Types of Printing for Packaging

Different technologies and techniques are used to print product packaging. Below are the various printing processes to be considered.

1. Offset lithography

Also known as litho or offset, this printing process commonly uses flexible (often aluminum) plates. The inked image is transferred from a plate to a rubber blanket and, finally, to the printed material or substrate.

Litho printing uses a CMYK (cyan, magenta, yellow, and black inks) color process, resulting in precise, sharp, and clean prints. This method provides high print quality and is intended for long packaging runs. The reusable plates offer cost benefits for repeat jobs and long print runs.

2. Flexography

Flexography (“flexo”) can be suitable for flexible and corrugated packaging and labels when printed in high volumes. The process, which utilizes a plate made from rubber, can print on paper, plastics, metals, and other materials, especially for food and beverages.

Flexo masters, cylinders or stereos, are made of rubber or polymer material. The quality of flexo printing can vary depending on the process, number of colors, and desired unit economics. Like litho printing, flexo plates are reusable, but the flexo process is intended for much longer print runs, ranging from hundreds of thousands to millions of units.

Flexo prints at very high speeds with low running costs.

3. Gravure

Also called rotogravure, gravure printing is a high-volume and high-speed printing process that involves engraving the image onto a printing cylinder and transferring it onto the printed surface. This method is commonly used for printing newspapers, magazines, and other high-volume work requiring excellent print consistency.

4. Screen printing

Screen or silkscreen printing is less common in packaging, but may be suitable for some unique applications. While a relatively slow process, screen printing is commonly used for dimensional shapes, promotional products, and pre-made packaging items such as bottles, cups, plasticware, and textiles.

5. Digital printing

Digital printing offers the advantage of minimal or no set-up costs or tool fees while still delivering print quality generally comparable to lithography and flexography. Unlike those analog printing technologies, digital print does not use a physical master or plate. Instead, the ink or toner is directly applied to the substrate.

Among the advantages of digital are that short runs are fast and cost-efficient. It enables customization, serialization, late-stage design changes, and versioning of packaging designs. Digital printing is widely used for various packaging applications such as labels, shrink sleeves, flexible packaging, corrugated boxes, and folding cartons.

- Toner: Toner printing, a first-generation digital printing technology, uses precision dot application but requires constant calibration for quality maintenance. It’s slower than inkjet printing and is typically utilized for shorter runs of paper-based packaging. Dry toner and liquid toner technologies are widely used in product packaging.

- ElectroInk (by HP Indigo): HP’s proprietary digital printing technology, ElectroInk, powers their advanced HP Indigo digital presses. These presses use an electrically charged liquid ink with small particle size, allowing high-quality and precise printing. HP Indigo is the preferred choice for digital packaging, including folding cartons, flexible packaging, shrink sleeves, and labels. It delivers exceptional results, especially for designs that demand uniformity and intricate detailing.

- Inkjet: Industrial inkjet printers presses transfer the image using small ink droplets from high-performance printheads. Inkjet is commonly used for color and monochrome printing, corrugated packaging, flexible packaging, labels, and folding cartons.

Product Packaging Design Process: 5 Steps

The product packaging design process is an exciting and crucial journey. Here’s what to consider and how your journey may look:

Factors to Consider

Designing product packaging requires anchors that help guide the entire process.

1. Branding

The packaging design should align with the brand’s visual identity. It should incorporate the same logo, colors, typography, and overall message as other brand-related materials. This cohesiveness helps maintain a strong and recognizable brand identity.

2. Content

The company should consider the packaging’s content carefully, including product information, instructions, regulatory requirements, and any additional messaging.

3. Budget

Design aspirations should match the available budget. Brands must consider cost-effective packaging solutions that balance affordability with quality and functionality.

4. Sustainability

With increasing consumer demand for eco-friendly packaging, brands should prioritize sustainable product packaging. They must consider the recyclability, reusability, or biodegradability of their packages.

Step-by-Step Guide

Here’s a general roadmap for a systematic and practical approach for packages that stand out.

1. Determine the customer

Select a target audience and research their demographics, preferences, and buying behavior to design packaging that resonates with them. Address their needs and appeal to their values to stand out in the market. Customers should be the basis of product packaging ideas.

2. Research the competition

Analyze competitors’ packaging strategies. Gain insights into industry trends, identify gaps, and differentiate the brand’s product through unique design elements, messaging, or materials.

3. Identify the brand and concept

Define brand identity, values, and positioning. Then translate them into visual elements such as logos, colors, and fonts to apply to packaging design. The concept should reflect the brand’s story and resonate with the target audience.

4. Know the product requirements

Consider the product’s size, shape, fragility, and other specifics to determine the appropriate materials and protective features. Research any regulatory information to include to plan the labels accordingly.

5. Print the packaging

Collaborate with professional printers or packaging manufacturers to bring the design to life. Ensure the accurate representation of colors, graphics, and text post-printing. Printing partners can recommend techniques and materials that match one’s desired aesthetic and budget.

Read the following for an in-depth exploration of the packaging design process:

- How to Perfect Your Product Packaging Design: A Guide

- The True Cost of Product Packaging: An Illustrated Guide

- A Guide to Selecting the Best Packaging Colors for Your Product

- Packaging Development Considerations: Inflation, Labor, Supply Chain

5 Product Packaging Trends to Know

In an ever-evolving marketplace, staying updated on the latest packaging trends is essential to meet shifting consumer expectations.

1. Sustainable packaging

Due to increasing environmental consciousness, sustainability is at the forefront of everyone’s concerns. Sustainable packaging solutions are gaining momentum.

Implementing strategies such as reducing material wastage and using recycled or renewable resources can help businesses align with sustainability goals. Companies can partner with a packaging converter to ease the transition to sustainable packaging.

2. Smart packaging

Smart packages integrate technology for innovative features. QR codes, near-field communication (NFC), and augmented reality enhance consumer engagement and information delivery.

For example, QR codes can bring certified leads to targeted websites, while NFC can ease product authentication. Augmented reality can offer detailed and realistic product viewings for remote customers.

3. Minimalist design

Less is more when it comes to today’s packaging design. Minimalism focuses on clean lines, simplicity, and clarity, allowing the product or branding to take center stage. You may have noticed it with many large brands cutting their logo’s complexity.

And packaging designs are following suit. Businesses remove unnecessary elements, use monochromatic color schemes, and employ whitespace to create simple but elegant designs.

4. Personalized packaging

Custom packaging delivering personalized experiences can make a lasting impact on consumers. Businesses incorporate individual names, unique messages, or customized designs on the packaging.

Coca-Cola’s “Share a Coke” campaign had bottles printed with unique names to create personal connections and encourage social sharing.

5. Interactive unboxing experiences

Savvy businesses are designing their packaging to be part of the appeal. They create exciting, memorable, and shareable unboxing experiences to surprise and delight customers.

Typical strategies can include hidden surprises, personalized notes, or interactive elements to elevate the unboxing experience. They generate social media buzz and positive word-of-mouth.

Discover the state of packaging in various industries with the following guides:

- 5 Sustainable Pharmaceutical Packaging Trends

- The 5 Latest Trends in Snack Food Packaging

- The 6 Latest Trends in Alcohol Packaging Design

Packaging: Your Brand’s Silent Salesperson

Investing in high-quality packaging that reflects your brand identity and resonates with your target audience can significantly impact your business’s success. Packaging serves as a valuable marketing tool, creating a lasting impression. It’s essential to continually evaluate and adapt your packaging design to meet changing consumer needs.

If you want a partner for your packaging design journey, consider partnering with Meyers! We offer custom packaging solutions for any industry. Talk to Meyers experts today to discuss your business’s needs.

Top Product Packaging FAQs Answered

Here are answers to five frequently asked questions about product packaging and the surprising complexity of its strategies.

Product packaging is a powerful marketing tool for capturing attention and influencing purchase decisions. It visually represents the brand and can differentiate products from competitors. Successful packaging significantly impacts sales and consumer perception.

Packaging can be a tangible representation of a brand’s values, positioning, and personality. Color, fonts, and imagery can evoke emotions and establish brand recognition. Packaging also reflects brand quality, innovation, and sustainability efforts.

Well-designed packaging should be functional, easy to use, and provide clear product information. It creates anticipation, delivers convenience, and distinguishes the product. It should align with the target audience’s preferences and address their needs.

Businesses can explore cost-effective packaging strategies to optimize costs while maintaining quality. These practices include using standard sizes and streamlining production processes. Efficient designs can significantly contribute to long-term cost savings.

To resonate with a specific demographic, businesses must consider their preferences, needs, and values. By tailoring elements such as colors, imagery, typography, and messaging, they can appeal to the audience’s aesthetic preferences. For example, using post-consumer recycled or PCR packaging can attract the eco-conscious younger crowd.