How Does RFID Work in Product Packaging and Labeling?

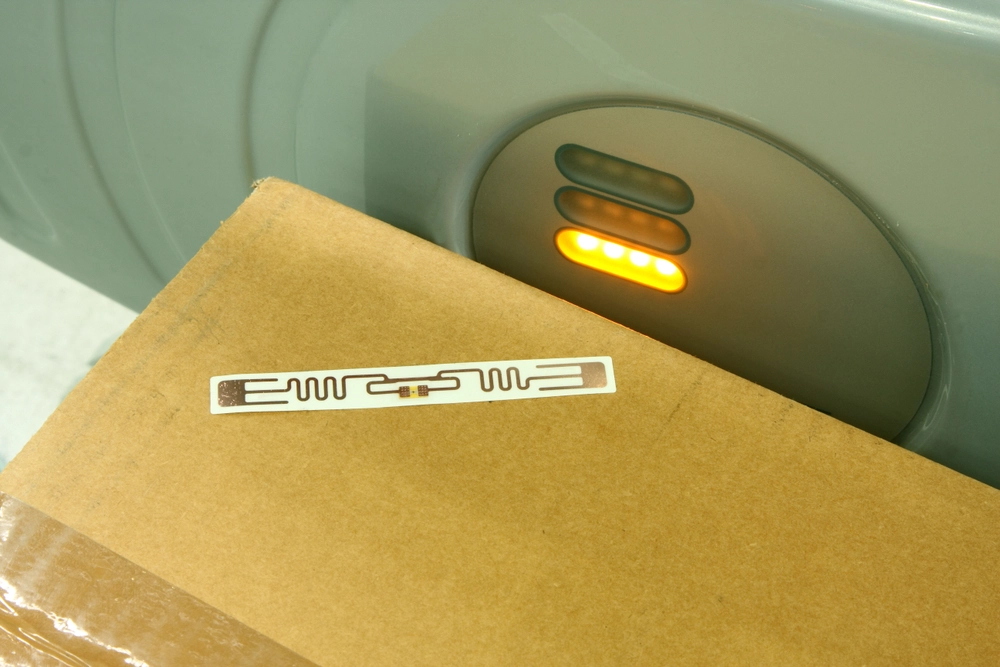

RFID, or Radio Frequency Identification, is a communicative technology system that uses electromagnetic fields to let users access digital data encoded into tags or smart labels. It consists of two components: the RFID reader and the tag.

An RFID reader consists of a scanning antenna and transceiver to activate the tag and transmit signals from the transponder or the RFID tag.

As millions of dollars are lost yearly due to inefficient supply chain processes and inadequate product packaging, RFID technology provides a smart packaging solution for industries worldwide. It enables companies to fulfill the customer’s high demands for quality packaging by smoothing any wrinkles in the shipment and delivery stage of fragile assets.

RFID packaging is a worthwhile investment helping improve supply chain quality, accountability, and data access. It would be best to learn what RFID is and how it works. With this article, suitably implement RFID in your brand’s custom packaging solutions and systems.

How Does RFID Work in Product Packaging and Labeling?

RFID technology makes it possible for every actor in the supply chain to track and access every product’s data, such as item description, location, and delivery instructions, whenever needed.

Manufacturing companies, distribution centers, and storage warehouses use RFID readers to scan the unique RFID tags in each asset’s packaging and label. Since RFID technology is self-aware, it automatically reads and writes product and package information at any point of a transaction—from item production to client delivery.

Common RFID Packaging Applications

In today’s Internet of Things (IoT) age, companies rely on RFID to bridge the gap between manufacturers and clients.

RFID packaging provides extra security for customers than an ordinary package label by sharing accurate and real-time information about their package. When shoppers scan a product label containing an RFID chip, they access external links that lead to the brand’s special offers.

Considered to be the future of barcodes in packaging solutions, RFID sensors read multiple tags simultaneously, regardless of angle, and even through most packaging materials. Unlike the accustomed barcodes, RFID withstands harsh conditions such as fluctuating environmental temperatures and exposure to sunlight and chemicals, to name a few.

There are two kinds of RFID systems: passive and active. Although both systems rely on radio frequencies to transmit data between tags and readers, they differ in some distinct ways. So, what are these RFID tags?

- Passive RFID tags are considered consumable and inexpensive technologies that only transmit stored data when it receives a signal from an RFID antenna. Companies can then keep and analyze the information collected, especially in retail, manufacturing, and warehousing. Passive RFID tags are used in the supply chain for access control and file tracking.

- Active RFID systems are commonly used to track the real-time location of tagged assets. On the other hand, they use battery-powered tags to continuously broadcast their signal to an RFID reader. Active RFID systems are typically bulkier than passive RFID tags, but they last about three to five years longer.

Advantages of Using RFID in Packaging

RFID technology has seen significant innovation and recognition growth in recent years. More companies are beginning to understand the benefits of using RFID systems for their supply chain management. Learn the advantages of using RFID for packaging with the list below.

1. Provides accurate safety information

Smart packaging has also led to significant progress in the food supply chain and industry. Recent advancements in RFID technology detect food property changes, such as humidity, temperature, gas, pH, conductivity, and dielectric constant. RFID technology can assure customers that their products comply with safety standards.

2. Increases product security

As mentioned, RFID systems automatically upload and collect electronic data. This capability minimizes transcription errors and duplication mishaps when collecting massive amounts of data if not prevented.

Package damage is a costly concern for many companies and consumers. With sensitivities ranging from 5G to 75G, RFID helps staff detect goods that may have issues right from the packaging. Some RFID tags turn red when it encounters a potentially damaging impact.

3. Monitors inventory

RFID tags make managing inventory easier without risking reliability and accuracy, especially for large warehouses that handle hundreds, if not thousands, of products daily.

For example, placing an RFID reader near the warehouse doorway keeps track of what products go in and out. With automatic real-time data tracking, readers also help locate misplaced individual products, equipment, or large asset inventory.

As mentioned above, readers communicate with over 100 tags per second. This capability enables the seamless performance of logistical tasks such as stock checks and audits. To illustrate, staff can obtain accurate data on an entire pallet load in a matter of seconds—saving valuable time and effort.

Get Smarter Packaging Solutions

From sustainability to more efficient delivery times, packaging solutions are constantly evolving to keep up with the ever-changing demands of consumers. Trends such as biodegradable packaging materials and smart packaging solutions are delivering more innovations to improve information management in companies across various industries every day.

If you’re interested in knowing more about sustainable and professional packaging solutions that fit your business’s needs, consider Meyers Printing. Our team of experts helps bring your ideal packaging solutions to life. Contact our experts today.