Soy Ink vs. UV Ink: Pros & Cons for Packaging and Printing

Selecting the right ink is a critical decision that can significantly impact the visual appeal and environmental footprint of your product packaging. As brands strive to meet the growing demands for packaging sustainability and efficiency, choosing the right ink type has emerged as a key consideration.

Soy ink is one of the notable ink types that presents a compelling proposition for brands aiming to reduce their environmental impact while maintaining high print quality. Its eco-friendly composition offers a greener alternative to conventional petroleum-based inks. Meanwhile, UV ink, with its rapid curing capabilities, promises increased productivity and versatility in printing operations. This can enable businesses to meet tight deadlines and deliver stunning, durable prints.

Understanding the key differences between these two inks provides brands with insights to inform their ink selection process. From the environmental benefits of soy ink to unlocking the efficiency gains offered by UV ink, this article will equip you with the knowledge required to make strategic packaging and print decisions that drive success in today’s competitive marketplace.

What is Soy Ink?

Soy ink is primarily composed of soybean oil, which serves as the ink’s main pigment carrier. Alongside soybean oil, soy-based ink formulations may also contain other renewable resources such as vegetable oils, resins, and natural waxes. These ingredients are carefully selected to ensure optimal ink performance while minimizing environmental impact.

In packaging and print, soy ink stands out as an eco-friendly alternative to conventional petroleum-based inks and other traditional inks derived from non-renewable fossil fuels. Moreover, soybeans are grown abundantly in many regions, making soy ink a readily available and environmentally responsible choice for printers and packaging manufacturers.

The Advantages of Soy Ink

This innovative ink formulation has gained popularity in recent years due to a number of environmental and practical advantages.

Sustainability

The most notable advantage of soy ink is its environmental sustainability. By utilizing renewable soybean oil as its primary ingredient, soy ink reduces reliance on finite fossil fuels and helps mitigate the environmental impact of printing and packaging processes.

Health and safety

Soy ink in printing is inherently safer for both human health and the environment compared to traditional petroleum-based inks. It contains lower levels of volatile organic compounds (VOCs), which are harmful air pollutants commonly found in conventional inks. As a result, printers and consumers are exposed to fewer potentially hazardous chemicals, promoting a healthier working environment and safer end products.

Print quality

Despite its eco-friendly composition, soy ink does not compromise print quality. It produces sharp colors and crisp text, making it suitable for many printing applications, including packaging labels, brochures, newspapers, and more. Soy ink’s excellent adhesion properties ensure long-lasting prints that withstand handling and environmental conditions.

Versatility

Soy ink is highly versatile and compatible with various printing substrates, including paper, cardboard, and some plastics. This versatility makes it ideal for diverse printing applications across different industries, from cosmetics packaging to marketing materials and publications.

Applications of Soy Ink in Printing and Packaging

Soy ink is utilized in a myriad of printing and packaging applications, including:

1. Food packaging

Due to its non-toxic nature and compliance with food safety regulations, soy ink is commonly used for printing on food packaging materials such as paperboard, cardboard, and flexible films. It ensures that printed packaging remains safe for direct food contact while maintaining visual appeal.

2. Cosmetics packaging

Soy ink is also popular in the cosmetics industry for printing labels, cartons, and tubes for various skincare, haircare, and beauty products. The resulting vivid print colors and eco-friendly benefits align well with the values of many natural and organic cosmetic brands.

3. Pharmaceutical packaging

Pharmaceutical companies often rely on soy ink for printing on medication packaging, inserts, and informational materials. Soy ink’s non-toxic composition and adherence to regulatory standards is crucial to ensure the safety and integrity of pharmaceutical products.

4. Marketing and promotional materials

Beyond product packaging, soy ink is utilized for promotional packaging materials such as gift boxes, promotional inserts, and limited-edition packaging designs. Vivid colors and high-quality prints can help brands convey their brand message effectively to create memorable and visually striking packaging experiences for consumers. Soy ink also adds a professional and eco-friendly touch to marketing collateral such as brochures, flyers, posters, and business cards.

5. Newspapers and magazines

Many publishers have transitioned to soy ink for newspaper and magazine printing, recognizing its environmental benefits and print quality advantages. Soy ink enhances the visual appeal of printed publications while reducing the industry’s overall carbon footprint.

What is UV Ink?

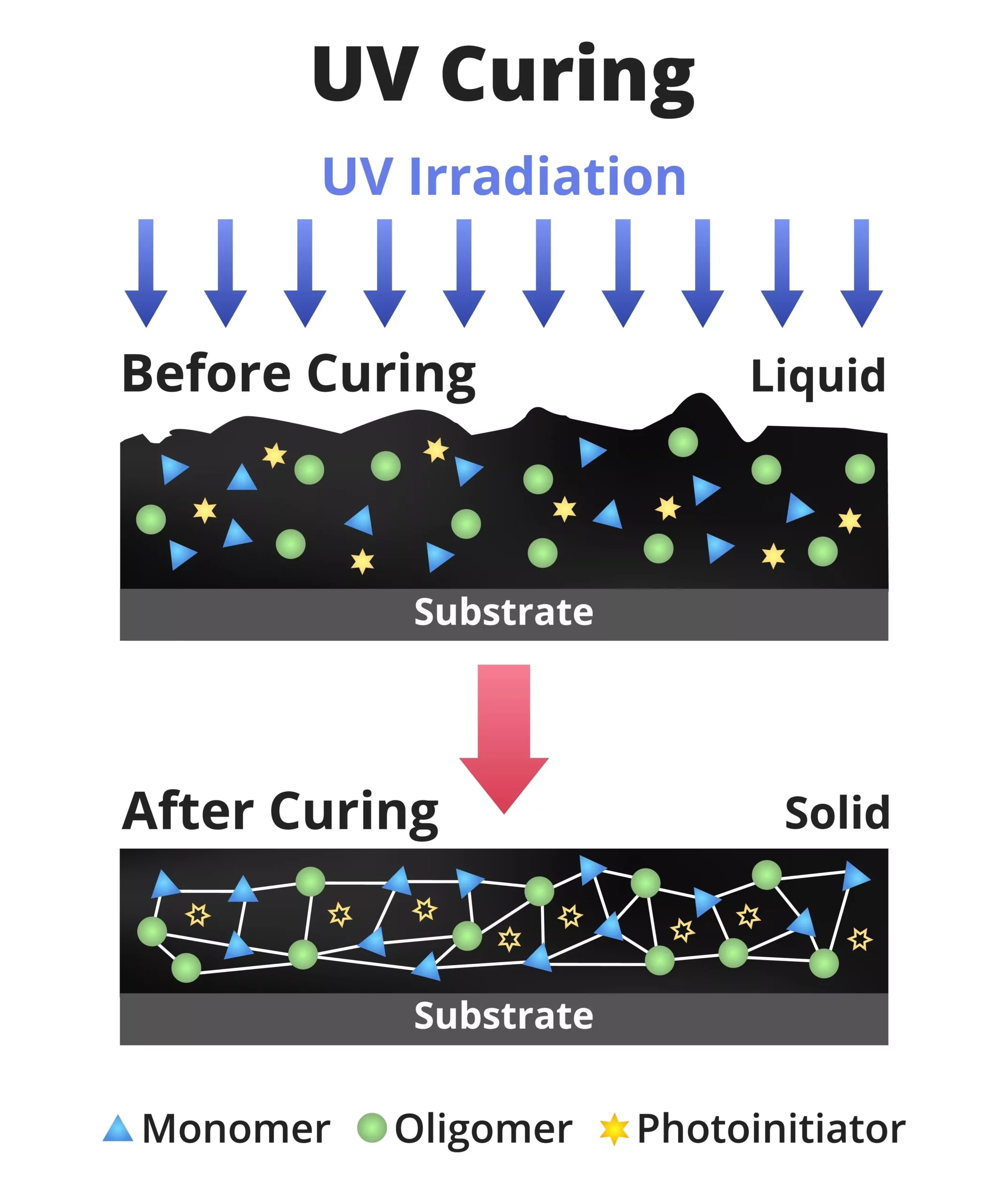

Ultraviolet (UV) ink is formulated using photopolymerizable materials that undergo a rapid chemical reaction when exposed to UV light. These materials typically include monomers, oligomers, pigments, and photoinitiators. Unlike solvent-based inks that rely on evaporation to dry, UV ink for printing cures almost instantly upon exposure to UV light, resulting in a hard, durable finish that adheres well to different substrates.

This innovative ink technology has gained prominence in packaging and print as a versatile and high-performance alternative to traditional solvent-based inks. It offers a range of benefits that make it well-suited for various applications since it can be formulated to meet specific printing requirements. This includes adhesion to different surfaces, flexibility, and resistance to various environmental factors.

Additionally, UV ink in printing is available in various formulations, including opaque, transparent, and specialty inks with unique properties such as texture or special effects.

The Advantages of UV Ink

UV ink’s ability to adhere to diverse substrates and resist environmental factors makes it an ideal choice for demanding printing projects across various industries. It serves as a versatile, high-performance solution with multiple benefits.

Rapid curing

UV ink cures almost instantly upon exposure to UV light, allowing for faster production speeds and increased productivity compared to solvent-based inks. This rapid curing process eliminates the need for drying time, reducing production turnaround times and enabling quicker delivery of printed materials.

Excellent print quality

UV printing produces sharp, vibrant colors and crisp details, resulting in high-quality prints with superior clarity and resolution. Quick curing ensures minimal dot gain and excellent color consistency, even on challenging surfaces.

Versatility

UV ink is highly versatile and can be used for a wide range of printing applications, including labels, packaging, signage, and specialty printing. It adheres well to various substrates, including paper, cardboard, plastics, metal, glass, and even coated surfaces, making it suitable for diverse printing projects.

Durability

Once cured, UV ink forms a durable, scratch-resistant finish that withstands handling, abrasion, and exposure to environmental factors such as moisture, heat, and UV radiation. This durability makes UV-printed materials useful for applications requiring long-lasting performance, such as outdoor signage, product labels, and industrial markings.

Applications of UV Ink in Printing and Packaging

UV ink finds widespread use in numerous printing and packaging applications, including:

1. Label printing

UV ink is commonly used to print product labels on various products, including beverages, cosmetics, pharmaceuticals, and consumer goods. Its fast curing time and excellent print quality ensure eye-catching, durable labels that stand out on store shelves.

2. Flexible Packaging

UV ink is also suited for printing on flexible packaging materials such as sachets, shrink sleeves, and pouches. Since it adheres well to flexible substrates and resists abrasion and moisture, the ink is excellent for packaging applications requiring durability and product protection.

3. Folding cartons

The ink is widely used for printing folding cartons used in the packaging of food, pharmaceuticals, electronics, and other consumer goods. Its quick curing time and superior print quality enable intricate designs, vibrant colors, and eye-catching finishes that enhance product visibility and appeal.

4. Specialty Printing

UV ink is used for specialty printing applications that require unique effects or finishes, such as spot varnishes, raised textures, embossing, and metallic or fluorescent inks. Its versatility allows for creative customization and brand differentiation in packaging and marketing materials.

5. Decorative Printing

Decorative printing applications, including interior décor, automotive trim, promotional items, and novelty products, also make use of UV ink effectively. Being able to adhere to various substrates and withstand environmental conditions also makes it useful for decorative applications requiring durability and visual impact.

Soy Ink vs. UV Ink: A Comparison

When choosing between soy ink and UV ink for printing and packaging applications, it’s essential to consider their respective pros and cons. While both inks offer unique advantages, they also have distinct characteristics that may influence their suitability for specific printing projects and business needs.

Pros of Soy Ink

- Environmental sustainability – soy ink is derived from renewable soybean oil, making it an eco-friendly choice compared to petroleum-based inks.

- Health and safety – the ink contains lower levels of volatile organic compounds (VOCs) and hazardous chemicals, promoting a safer working environment.

- Print quality – it produces sharp colors and text, making it suitable for industry-wide printing applications.

- Biodegradability – soy ink has a higher amount of biodegradable ingredients than traditional inks, reducing its environmental impact and promoting sustainable printing practices.

Cons of Soy Ink

- Longer drying time – soy ink may have a longer drying time compared to UV ink, due to a lack of evaporative solvents typically in the form of VOCs. This can affect production turnaround times.

- Limited substrate compatibility – the ink may not adhere well to certain substrates, requiring additional surface treatments or primers for optimal adhesion.

- Color variability – soy ink’s color consistency may vary depending on factors such as substrate type, ink formulation, and printing conditions.

Pros of UV Ink

- Rapid curing – UV ink cures almost instantly upon exposure to UV light, allowing for faster production speeds and increased productivity.

- Excellent print quality – it produces sharp, vibrant colors and crisp details, resulting in high-quality prints with superior clarity and resolution.

- Versatility – UV ink is highly versatile and can be used for a wide range of printing applications on various substrates.

- Durability – once cured, UV ink forms a durable, scratch-resistant finish that withstands handling, abrasion, and environmental factors.

Cons of UV Ink

- Environmental concerns – UV ink may contain chemicals that pose environmental and health risks if not handled properly during printing and curing processes.

- Initial investment – the equipment required for UV printing, including UV curing units, may involve higher upfront costs compared to traditional printing methods.

- Limited substrate compatibility – while UV ink adheres well to many substrates, it may not be ideal for certain heat-sensitive materials or non-flat surfaces.

Both soy ink and UV ink offer distinct advantages and considerations for printing and packaging applications. Businesses should carefully evaluate their specific needs, environmental priorities, substrate requirements, and budget constraints when choosing between these ink types.

Sustainable Paths Through Ink Innovation

The choice between soy ink and UV ink represents more than just a selection of ink type—it’s a strategic decision that can shape the sustainability, efficiency, and overall success of your brand. By exploring these two ink technologies, it’s clear that each offers unique advantages and considerations for businesses seeking to elevate their printing and packaging capabilities.

As you navigate the complexities of ink selection for your printing and packaging needs, discover the full range of print solutions available at Meyers. With expertise in sustainable printing practices, cutting-edge technologies, and commitment to customer satisfaction, Meyers is your trusted sustainable packaging manufacturer in achieving printing excellence. Contact the team of experts and learn the innovative packaging solutions that can propel your business forward.