What are Pressure-Sensitive Labels? Uses, Benefits & More

Pressure-Sensitive Labels for Every Industry

Great packaging starts with the details—and pressure-sensitive labels are one of the most important. They don’t just share information; they shape how consumers perceive your product. Most Americans depend on labels for accurate product details, making well-designed, effective pressure-sensitive labels essential for building trust and driving purchasing decisions.

Among the many labeling options available, pressure sensitive labels—also known as PS labels—stand out for their incredible flexibility. With so many possible combinations of adhesives, face stocks, panels, inks, coatings, and die cuts, PS labels are one of the most adaptable—and cost-effective—marketing tools a business can use.

Brands can easily customize label designs with PS labels to meet evolving market demands. They provide a vibrant canvas for brand communication, from eye-catching graphics to informative panels.

A pressure-sensitive label is a self-adhesive packaging element that adheres to surfaces upon the application of pressure. It requires no additional activation, such as heat or water, making it a versatile and widely used solution in product packaging across industries.

PS labels can handle any design, from simple, minimalist labels to bold colors with creative fonts. The creative options are limitless.

The simplicity of application also lets companies avoid obsolescence due to shifting regulatory policies regarding extended producer responsibility (EPR). Organizations can purchase standard, undecorated primary packaging and implement late-stage product differentiation by applying PS labels, effectively future-proofing their packaging against new environmental regulations.

Understanding Pressure-Sensitive Labels

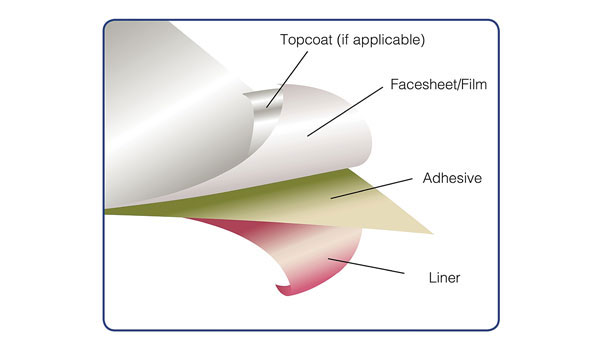

Pressure sensitive labels are self-adhesive labels that stick to surfaces when pressure is applied. These versatile labels serve numerous industries for product labeling, packaging, and branding. A pressure-sensitive label consists of three primary layers: the face stock, adhesive, and liner. The face stock forms the top layer where product information and graphics appear. The adhesive layer makes the label stick to the surface, while the liner protects the adhesive until the label is ready for application.

These labels offer businesses a flexible and easy-to-use labeling solution. They can be customized to meet specific business needs and requirements, and manufactured from various materials, including paper, plastic, and foil. This adaptability makes them suitable for diverse applications, from everyday consumer goods to premium or luxury products. Additionally, pressure-sensitive labels provide a cost-effective option for product labeling and can be designed with sustainability in mind, aligning with environmentally responsible practices.

How Pressure-Sensitive Labels Work

Pressure sensitive labels create an instant bond when pressure is applied to the label surface. Unlike other label types, they require no activation of the adhesive with heat, water, or solvents. The adhesive layer is engineered to be flexible and flow across surfaces when pressure is applied, ensuring a strong and durable bond. This makes pressure-sensitive labels exceptionally easy to apply, requiring minimal effort while providing reliable performance.

The adhesive used in pressure-sensitive labels represents a critical component of their functionality. Manufacturers formulate these adhesives to resist various environmental conditions, such as temperature fluctuations and humidity, ensuring that labels remain securely attached even in challenging environments. This makes pressure sensitive labels ideal for products that must withstand different conditions, from refrigerated goods to items exposed to outdoor elements. Understanding how pressure sensitive labels work helps businesses select the right labeling solution for their specific requirements.

Components of Pressure-Sensitive Labels

Here are the primary components of pressure-sensitive labels:

1. Face Stock

The outermost layer of a PS label, often referred to as the facestock, is typically made from materials such as paper, film, or foil. This layer provides a printable surface for custom-printed labels, allowing for extensive customization options to display product information and graphics.

2. Adhesive Layer

Pressure sensitive adhesive enables the label to adhere to surfaces upon the application of pressure. It can vary in tackiness and composition depending on the packaging material and supply chain requirements. For example, a product destined for freezer storage will need different adhesives than one intended for standard shelf display.

3. Release Liner

The backing material protects the adhesive layer until application. It is usually made of paper or film treated with a release coating to facilitate easy removal during the application, especially important for paper labels.

Printing Methods for Pressure-Sensitive Labels

PS labels utilize two primary printing methods: digital and flexographic printing. These methods offer extensive customization options, making them ideal for creating custom pressure sensitive labels that meet specific product needs. The label design, quantity, and intended environment all influence which method proves more appropriate.

Digital Printing

Digital printing transfers images directly onto the label material without using plates. This method delivers high-quality, customizable prints suitable for shorter print runs and variable data applications. For instance, if a company needs 150,000 labels across 25 SKUs (stock-keeping units) for frozen products, they will likely use a petroleum-based facestock with freezer-grade adhesive printed digitally.

Flexographic Printing

Flexographic printing employs flexible relief plates to transfer ink onto the label material. It excels in high-volume production with fast printing speeds and supports various substrates. Using the same example above, 150,000 labels for just 3 SKUs of similar-sized vitamin products might benefit from flexographic printing on paper material with an all-temperature adhesive.

Hybrid Printing

Hybrid flexo printing combines the strengths of both digital and flexographic printing in a single process. This method offers the flexibility and customization of digital printing—ideal for variable data or frequent design changes—while leveraging the efficiency and cost-effectiveness of flexographic printing for larger volumes. In the earlier example, if a company needs 150,000 labels for 10 SKUs of premium coffee products, hybrid printing could be the ideal solution, using digital technology for SKU-specific artwork and flexo for consistent elements like logos or backgrounds—all on a textured paper facestock with a permanent adhesive.

Substrates and Finishes for Pressure-Sensitive Labels

The choice of substrates and finishes significantly influences the appearance, durability, and information clarity of PS labels. Pressure-sensitive label materials come in various options, each with unique characteristics that address different needs and preferences.

1. Types of Materials Used

Manufacturers create PS labels from various materials, including paper, film, foil, and synthetics. Unlike shrink sleeve labels, which risk graphic distortion due to their application method, pressure-sensitive labels perform best on smooth surfaces and offer reliable performance across various product substrates. Each material presents unique characteristics, such as durability, moisture resistance, flexibility, and environmental impact. These diverse materials accommodate different applications, ensuring labels withstand various conditions while maintaining visual appeal and functionality.

2. Finishing Options

Finishing options encompass a spectrum of choices, including glossy, matte, and specialty coatings. Sleeve labels offer extensive customization options, allowing each layer to be tailored to meet specific packaging requirements. Glossy finishes create a vibrant, shiny appearance that stands out on store shelves where products must compete for attention. Matte finishes provide a more subdued, elegant look with reduced glare.

Depending on the desired effect, specialty coatings such as UV protectants or varnishes can add additional protection and visual enhancement. For example, RFID labels often benefit from waterproof finishes to protect their functionality in various environments.

Designing and Applying Pressure-Sensitive Labels

Designing and applying pressure-sensitive labels requires careful consideration of several factors to ensure effectiveness and brand alignment.

Effective Label Design

The product label design should communicate clearly, remain easy to read, and maintain consistency with the brand’s identity. It must also possess sufficient durability to withstand various environmental conditions, ensuring information legibility and label integrity throughout the product lifecycle.

Proper Application Techniques

When applying pressure-sensitive labels, surface preparation plays a crucial role. For optimal results, surfaces should be clean and smooth to ensure a strong bond. Depending on production scale, labels can be applied manually or using automated labeling equipment. This flexibility makes pressure-sensitive labels suitable for both small businesses and large-scale operations.

Customization Options

Customization represents a key advantage of pressure-sensitive labels. Businesses can design labels to include various elements, such as barcodes, logos, and text, tailored to their specific requirements. The label materials can also be customized, with options including paper, plastic, and foil, to meet different performance needs. Additionally, adhesives can be formulated to provide either removable or permanent attachment, with resistance to various environmental conditions, such as temperature fluctuations and humidity.

A Flexible Labeling Solution

Overall, pressure-sensitive labels offer a versatile and convenient labeling solution that adapts to specific business needs. Their ease of application and extensive customization options make them a popular choice for businesses seeking efficient and effective labeling solutions.

Common Pressure-Sensitive Label Applications

Pressure-sensitive labels serve diverse applications across various industries due to their flexibility, durability, and customization capabilities. They particularly appeal to brands seeking custom labels that address specific product requirements and withstand challenging conditions. Here are some common applications:

1. Retail Packaging

In retail environments, PS labels commonly serve shelf and price labeling purposes, allowing convenient price adjustments and display of essential product details. Retailers frequently utilize them for promotional purposes, creating attention-grabbing labels for discounts or special offers.

PS labels play a crucial role in branding fast-moving consumer goods such as food, beverages, cosmetics, and personal care products. They effectively resist environmental factors while providing ample opportunities for vibrant, distinctive branding.

2. Logistics and Shipping

PS labels prove indispensable throughout logistics and shipping operations, functioning as address labels and clearly displaying critical shipping information. Organizations also implement them for inventory management and tracking to ensure efficient handling and accurate delivery of goods.

Since shipping depends on clear labels with unique information for each package, the easy customization and versatility of PS labels make them ideal for communicating information clearly and accurately. Logistics companies can also apply product identification measures such as barcodes, QR codes, serial numbers, and batch information on virtually any packaging type.

3. Healthcare and Pharmaceuticals

Healthcare providers rely on PS labels for prescription labeling, ensuring accurate medication administration and enhancing patient safety. These labels also serve a crucial role in medical device labeling, providing essential information for proper use and regulatory compliance.

Many pharmaceutical PS labels incorporate tamper-evident features, ensuring product integrity and compliance with stringent regulatory requirements.

4. Industrial and Manufacturing

PS labels serve numerous purposes in industrial settings. Manufacturers use them for labeling machinery, tools, and components – facilitating efficient inventory management and asset tracking.

They also play a critical role in hazard and safety labeling, providing crucial warnings and instructions for safe operation in industrial environments. PS labels frequently mark hazardous areas, machinery, and chemicals, significantly reducing accident risks.

PS labels can withstand harsh industrial conditions, including exposure to chemicals, moisture, and high temperatures, maintaining readability and adhesive strength even in the most challenging environments.

The Impact of a Reliable PS Label

The choice of labels not only conveys crucial information but, more importantly, shapes consumer perceptions about your brand and product. When first impressions matter, pressure-sensitive labels offer the most reliable, impactful, and cost-effective option across industries.

Get in Touch for Your Custom Labeling Needs

Ready to optimize your labeling strategy with pressure sensitive labels that enhance your product experience and brand image? Contact Meyers today to discuss your custom pressure-sensitive label needs. Our team of experts will help bring your vision to life with solutions tailored to your specific packaging requirements.