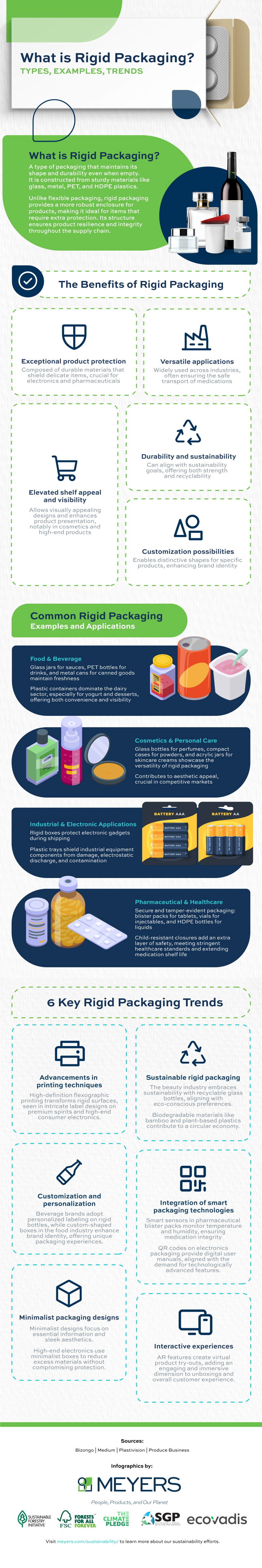

What is Rigid Packaging? Types, Examples, Trends

Product packaging is a critical aspect across industries, often influencing consumer perceptions. Businesses from diverse markets strive to create packaging that’s not only durable and protective but also visually appealing. Thus, choosing the right packaging can be a complex process.

Among these product packaging types, rigid packaging stands out for its extensive range of applications. Robust and reliable, it offers durability and protection for various products, from cosmetic products on a store shelf to products in the industrial sector.

This infographic explains what rigid packaging is, its advantages, its common applications, and notable trends showing why it is widely used in the industry today.

Jump to a Section:

- What is Rigid Packaging?

- The Benefits of Rigid Packaging

- Common Rigid Packaging Examples and Applications

- 6 Key Rigid Packaging Trends

What is Rigid Packaging?

Rigid packaging is a type of packaging that is sturdy, inflexible, and maintains its shape even when empty. Its structural strength and durability provide robust protection and preservation for various products throughout their lifecycle. Rigid packaging consists of materials with inherent rigidity, such as glass, metal, and specific plastics like PET and HDPE.

This packaging is widely used across various industries to protect and present a diverse range of products, providing structural integrity throughout the supply chain. It is particularly suitable for items that require extra protection, such as fragile goods, electronics, pharmaceuticals, and high-end consumer products.

Unlike flexible packaging, which includes materials such as bags and pouches, rigid packaging offers a more solid and protective enclosure for products.

Rigid packaging materials typically offer a range of characteristics:

- Glass – has inert qualities and the ability to preserve the purity of contents. Finds its niche in premium beverages and specialty products.

- Metal – its resilience and impermeability are ideal for a variety of foods, ensuring prolonged shelf life.

- Rigid plastics – specific plastics such as PET and HDPE offer versatility. PET’s lightweight durability is ideal for beverages, while HDPE excels in safeguarding pharmaceuticals and chemicals.

The Benefits of Rigid Packaging

Rigid packaging offers specific advantages across industries, making it a preferred choice for many businesses. The following benefits set rigid packaging apart.

1. Exceptional product protection

Rigid materials, such as durable plastics, glass, and metal, serve as robust shields against external elements like pressure, impact, and temperature fluctuations. This is particularly crucial for industries dealing with delicate or high-value items, particularly electronics, cosmetics, and pharmaceuticals.

2. Versatile applications

Rigid packaging’s adaptability to various product types and industry requirements positions itself as a widely used packaging solution. For instance, in the electronics sector, rigid packaging ensures the safe transport of fragile devices, minimizing the risk of damage during transit. In the pharmaceutical sector, rigid packaging ensures the protection of medications, maintaining their efficacy and integrity throughout the distribution chain.

3. Elevated shelf appeal and visibility

The structural integrity of rigid packaging allows for intricate and visually appealing designs, catering to premium product segments. Transparent materials such as glass and specific plastics offer consumers a clear view of the enclosed product.

This transparency not only showcases the product’s quality but is also a common feature in sectors like cosmetics, where customers appreciate seeing the color and texture of the product before purchase.

4. Durability and sustainability

Rigid packaging materials, particularly recyclable plastics and glass, align with the growing emphasis on sustainable practices while offering durability. For example, glass bottles used in the beverage industry are not only sturdy but also highly recyclable, supporting sustainability goals and potentially reducing a brand’s environmental footprint.

5. Customization possibilities

The rigidity of packaging materials allows for intricate shapes and structural designs for specific applications. This customization can enhance brand identity, making products easily recognizable and memorable on the shelf.

In the beauty and cosmetics industry, brands often utilize uniquely shaped rigid packaging to establish a distinctive and memorable presence amongst the competition.

Common Rigid Packaging Examples and Applications

1. Food and beverage

Rigid packaging plays a pivotal role in preserving the freshness and integrity of food and beverages. Common examples include glass jars for sauces and condiments, PET bottles for carbonated drinks, and metal cans for canned goods.

The robust nature of rigid packaging ensures protection against external elements, maintaining the quality and taste of the enclosed products. In the dairy sector, rigid packaging in the form of plastic containers is widely used for yogurt and desserts, providing convenience and product visibility.

2. Cosmetics and personal care products

The cosmetics industry relies on rigid packaging to not only protect delicate formulations but also to enhance the products’ visual appeal. Examples include glass bottles for premium perfumes, compact cases for powders, and acrylic jars for skincare creams.

The durability of materials such as glass or high-quality plastics ensures the safe transportation of cosmetic items. Meanwhile, custom, intricate designs contribute to the overall aesthetics, supporting brand positioning in the competitive beauty market.

3. Industrial and electronic applications

In the industrial and electronic sectors, rigid packaging is essential for safeguarding delicate and often expensive components. Electronic gadgets come packaged in rigid boxes, providing structural support and protection during shipping.

Industrial equipment, especially small and sensitive parts, utilize rigid plastic trays or clamshells. These packaging solutions prevent damage, electrostatic discharge, and contamination, ensuring the products reach end-users in optimal condition.

4. Pharmaceutical and healthcare

Pharmaceutical products demand secure and tamper-evident packaging to maintain their efficacy and comply with regulatory standards. Rigid packaging in this sector includes blister packs for tablets, vials for injectables, and high-density polyethylene (HDPE) bottles for liquids.

Child-resistant closures are often integrated into rigid pharmaceutical packaging to ensure the safety of users, aligning with stringent healthcare requirements. The use of rigid materials guarantees the protection of sensitive medications from external factors and extends their shelf life.

6 Key Rigid Packaging Trends

1. Advancements in printing techniques

Advancements in printing techniques have revolutionized branding and visual appeal in the product packaging industry overall. High-definition flexographic printing allows for intricate details on rigid surfaces, providing a canvas for captivating designs. This is particularly evident in the beverage industry, where premium spirits showcase intricate label designs achieved through advanced printing technologies.

Lithographic printing on rigid materials enhances color vibrancy and consistency, contributing to a polished and professional aesthetic, as seen in high-end consumer electronics packaging.

2. Sustainable rigid packaging

Sustainability is a driving force in packaging trends, and rigid packaging is no exception. Innovations include the use of recycled and recyclable materials for rigid packaging solutions.

For example, there’s a growing shift toward sustainable cosmetic packaging in the beauty industry. Glass bottles and jars can emphasize recyclability and reduced environmental impact. These eco-friendlier materials used in rigid packaging align with current consumer preferences while contributing to a circular economy.

Companies are also adopting biodegradable materials such as bamboo, molded pulp, and plant-based plastics, resulting in sustainable rigid packaging.

As sustainability continues to take center stage, there’s also a notable trend towards reusable packaging. Particularly in the food industry, reusable rigid containers and boxes are becoming more prevalent, reducing single-use plastic waste.

3. Customization and personalization

Customization and personalization allow brands to create unique and memorable experiences. Beverage brands can adopt personalized labeling on rigid glass or PET bottles. In the food industry, custom-shaped rigid boxes with unique opening mechanisms contribute to a distinctive brand identity. This trend enhances consumer engagement by providing a tailored and exclusive packaging experience.

4. Integration of smart packaging technologies

Smart packaging technologies are increasingly integrated into rigid packaging to provide enhanced functionality. In the pharmaceutical sector, blister packs now incorporate smart sensors to monitor temperature and humidity, ensuring the integrity of medications.

Additionally, QR codes on rigid packaging in the electronics industry enable consumers to access digital user manuals, contributing to more product interaction. This trend reflects a growing demand for technologically advanced features that complement the rigid packaging’s protective attributes.

5. Minimalist packaging designs

A trend on minimalist packaging designs has emerged, emphasizing simplicity and sustainability. Rigid packaging in this context focuses on essential information and sleek aesthetics.

High-end electronics typically utilize minimalist rigid boxes, reducing excess materials without compromising product protection. This trend also caters to either eco-conscious consumers or those seeking a clean and modern look.

6. Interactive experiences

Rigid packaging is evolving to provide interactive experiences for consumers as well. Augmented reality (AR) features on packaging enable customers to virtually try products before purchase. This trend adds an engaging and immersive dimension to rigid packaging, enhancing product unboxings or overall customer experience.

A Sturdy Path to Packaging Excellence

Rigid packaging remains a reliable and versatile choice for businesses across different industries. Understanding how widely used packaging types such as this are is essential for making informed decisions about packaging strategies.

Trends in rigid packaging involving printing techniques, the growing emphasis on sustainability, a surge in customization and personalization, and the integration of smart packaging technologies reflect a fast-paced packaging industry.

Brands navigating this landscape with a strategic understanding of key developments can not only optimize their packaging choices but also position themselves as leaders in innovation and consumer preference.

If you’re planning to leverage packaging to amplify your brand’s impact, explore the possibilities with the packaging experts at Meyers. Ensure product integrity and captivate consumers with expert collaboration and custom packaging solutions tailored to your business.