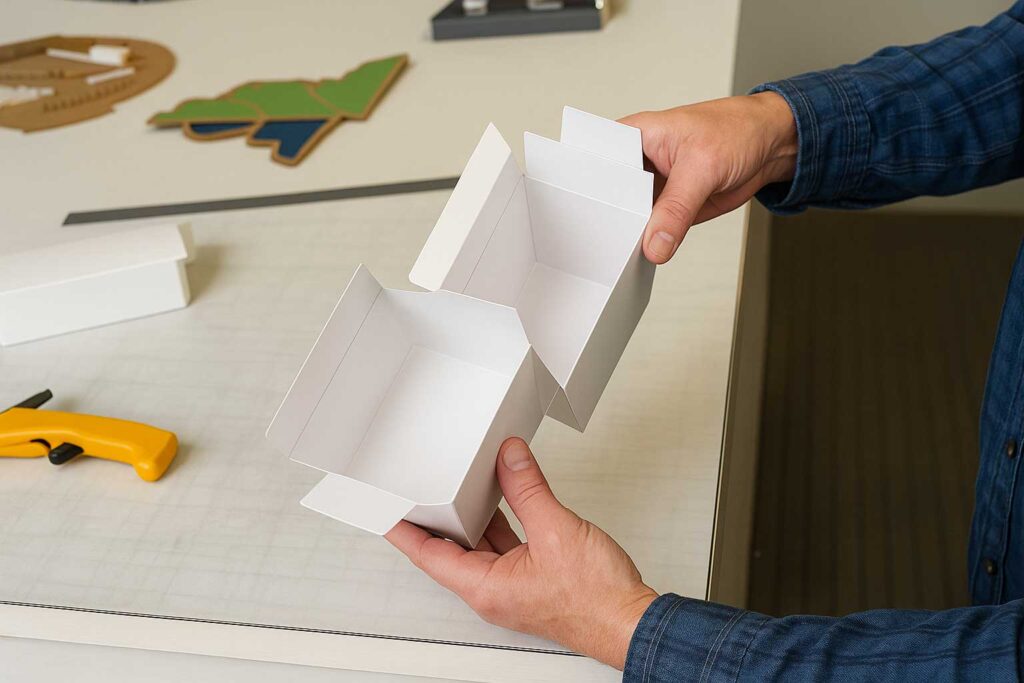

Folding Carton Manufacturer

Delivering Impactful Packaging Through Precision Printing

Meyers is a U.S.-based folding carton manufacturer producing paperboard cartons for food, beverage, health, beauty, and consumer goods brands. Folding carton manufacturing at Meyers includes material selection, structural design, printing, converting, and fulfillment to support retail and distribution packaging programs.

We manufacture custom folding cartons using advanced printing and converting equipment, with a focus on consistency, repeatability, and domestic production.

Folding Carton Manufacturer

Delivering Impactful Packaging Through Precision Printing

Meyers is a U.S.-based folding carton manufacturer producing paperboard cartons for food, beverage, health, beauty, and consumer goods brands. Folding carton manufacturing at Meyers includes material selection, structural design, printing, converting, and fulfillment to support retail and distribution packaging programs.

We manufacture custom folding cartons using advanced printing and converting equipment, with a focus on consistency, repeatability, and domestic production.

Folding Carton Printing Methods Tailored to Your Product Needs

Choosing the right printing method impacts appearance, performance, and cost efficiency. As a folding carton manufacturer, Meyers offers multiple printing technologies to support different production volumes, design requirements, and timelines.

Offset Printing

Offset involves a sequence of rotating cylinders that print the ink onto the material, typically paper. In particular, the advantage of offset printing is that businesses can print numerous items quickly. Therefore, it’s the ideal technique for large product orders.

Digital Printing

In contrast, digital printing uses inkjet or electrophotographic imaging technologies to apply designs directly onto the material. Although traditional methods like lithography or flexography are known for their exceptional quality, it’s worth noting that modern digital printing technologies can now produce results that appear just as premium, often rivaling offset in visual appeal. Additionally, digital printing requires minimal setup and offers fast turnaround times, making it especially suitable for short runs, prototypes, or personalized packaging, thanks to the lack of printing plates or extensive prep work.

Flexography

Finally, flexographic printing shares similarities with lithographic (offset) printing, particularly in its use of rotating cylinders to apply ink. However, what sets flexography apart is its ability to handle a wide range of substrates. Specifically, it’s ideal for non-porous materials such as film and foil. Because of this, flexographic printing is commonly used for folding cartons, labels, and other specialized packaging formats that require both flexibility and durability.

Folding Carton Manufacturing Capabilities

Premium Finishes and Converting Capabilities for Folding Cartons

As a U.S.-based folding carton manufacturer, Meyers delivers cartons engineered for structural performance and visual consistency. Converting capabilities include high-speed die cutting, precision folding and gluing, and quality control processes designed to support repeatable results across production runs.

Stunning Carton & Box Finishings

SEE OPTIONS

A Carton Manufacturer for Multiple Industries

Meyers manufactures folding cartons for regulated and performance-driven industries where consistency and compliance matter. Manufacturing processes are adapted to meet industry-specific requirements related to materials, print quality, and packaging performance.

- Food and Beverage

- Health and Beauty

- Life Sciences

- Household CPG Products

- Electronics

- Pet Products

- Nutraceuticals

End-to-End Carton Manufacturing Process

Meyers provides end-to-end folding carton manufacturing services, from early material selection through final shipment. This integrated approach supports production efficiency and quality control throughout the lifecycle of a packaging program.

- Step 1: Material selection including FSC and SFI-certifed paperboard, SBS, CRB, and URB

- Step 2: Structural design and prototyping

- Step 3: Printing using offset, digital, flexographic, and hybrid methods

- Step 4: Finishing and embellishments

- Step 5: Folding, gluing, Quality control, shipping

Sustainable Folding Carton Manufacturing

Sustainable folding carton manufacturing focuses on responsible material sourcing, efficient production, and waste reduction. Meyers integrates sustainability practices across printing, converting, and fulfillment to support brand and regulatory requirements.

Fulfillment & Inventory Solutions for Your Retail Packaging Boxes

Beyond manufacturing, Meyers supports folding carton programs with integrated fulfillment and inventory services. These services are designed to help brands manage distribution, reduce handling, and improve supply chain predictability.

Sustainability Through Smarter Fulfillment

• Reduce carbon footprint with fewer trucks and fewer expedited air shipments

• Lower manufacturing waste and improve use of raw materials and ink

• Help brands meet sustainability and ESG goals

Operational Efficiency

• On-demand fulfillment and shipping to meet changing demand

• Secure, climate-controlled warehousing for sensitive or seasonal products

• Fewer production setups and reduced resource usage for large-scale runs

Cost Advantages

• Larger batch runs lower per-unit production costs

• Fewer rush fees and expedited shipments needed

• Improved demand prediction and inventory management to minimize waste

For brands evaluating folding carton packaging partners, integrated manufacturing and fulfillment can help reduce lead times, simplify logistics, and improve supply chain reliability. Meyers’ fulfillment services are designed to support these goals as part of a complete packaging program.

The Future of Folding Carton Manufacturing: Trends and Market Context

Market Statistics

Meyers stays at the forefront of the evolving global packaging landscape, helping brands adapt to rising demand for sustainable, cost-effective, and custom solutions. For context, Mordor Intelligence reports that the global folding carton market reached $148.47 billion in 2023 and is projected to grow to $186.09 billion by 2028. This growth is largely fueled by increasing expectations for packaging that supports brand identity, product protection, and environmental responsibility. This surge is driven by increasing expectations for packaging that supports brand identity, product protection, and environmental responsibility.

As a result, this momentum presents a key opportunity for brands seeking strategic packaging partners who can scale efficiently, maintain high standards, and align with sustainability goals. Our team works with forward-thinking companies that value high-performance paperboard packaging and flexible, technology-driven production models.

Consumer Preferences

Consumer preferences are shifting, too. In fact, research from WWF Singapore shows that 1 in 3 shoppers now prefer sustainable packaging for online purchases. To help brands respond, Meyers d elivers recyclable cartons that combine strong visual impact with responsible sourcing practices.

Beyond that, even the base material delivers long-term value: paperboard can be recycled up to 25 times, according to Graz University of Technology. This makes it a smart, circular packaging choice for CPG brands aiming to reduce environmental impact without compromising on design.

Folding Carton Manufacturing FAQs

Folding Carton Insights & Resources

U.S. Packaging and Labeling Requirements: FDA, FTC, and FPLA Explained

How PCR Packaging Supports Your Goals and Your Customers’ Expectations

16 pt vs 28 pt Cartons: How to Choose the Right Thickness for Your Carton Packaging

Last Updated on January 12, 2026