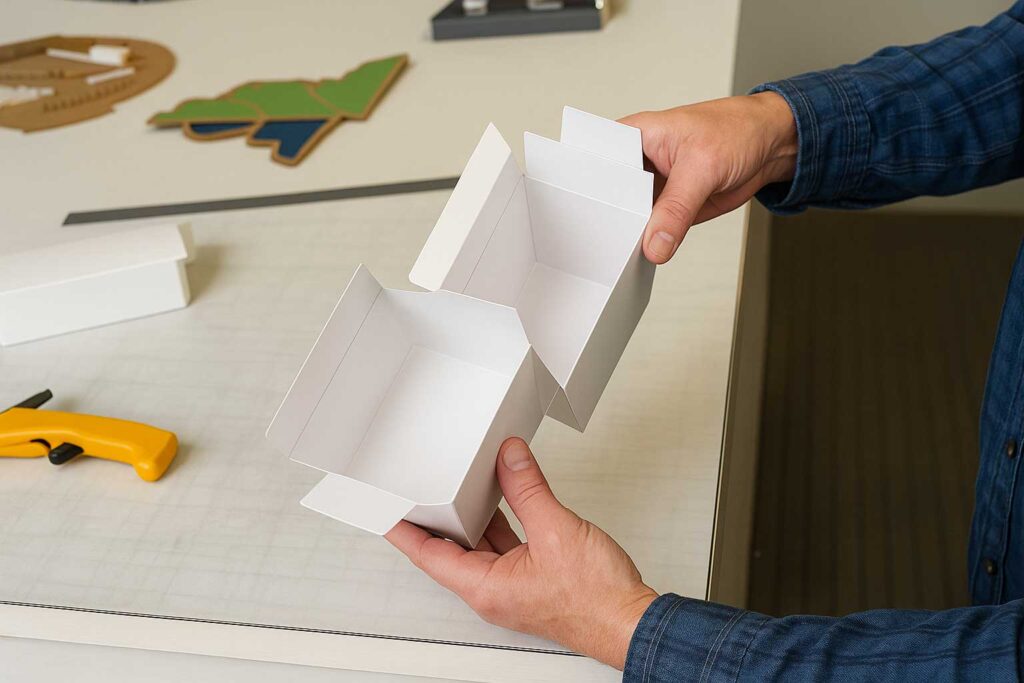

Folding Cartons

Custom Folding Carton Packaging for CPG Brands

Our folding carton solutions support both emerging and national brands with multi-SKU product lines, retail rollouts, and ongoing packaging programs that require higher production volumes. From regional expansion to national distribution, we help brands maintain consistency and quality at scale.

Packaging Designed for Durability and Shelf Appeal

Folding cartons are designed to balance durability, visual appeal, and efficiency. Each carton is tailored to product dimensions, branding requirements, and retail handling needs, helping brands maintain consistency from packing through point of sale.

Our printing technology delivers precise, consistent color and quality from first impression to unboxing. Since 1949, Meyers has helped brands create CPG packaging that stands out on every shelf.

Explore other solutions:

Key Considerations for Folding Carton Packaging

Sustainability

Responsibly sourced paperboard and recyclable materials are commonly used in folding carton packaging.

Design Flexibility

Carton styles, finishes, and structural options that support branding and retail requirements.

Integrated Solutions

Optional features such as RFID-enabled packaging for visibility and compliance.

Finding the Best Carton Style for Product Safety and Shelf Impact

Every product deserves packaging that fits perfectly, in form, function, and finish. The right folding carton style improves product protection, enhances usability, and elevates your brand’s presence on the shelf.

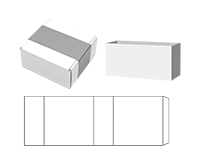

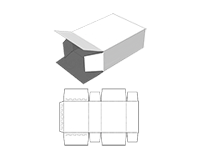

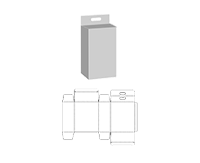

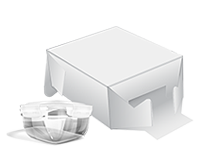

Explore our most popular carton styles, each engineered for performance and visual appeal:

Popular Packaging Styles for Folding Cartons

Not sure which carton style fits your product best? Our packaging experts can help you choose a design that meets your brand, shipping, and retail needs.

Packaging Solutions by Industry

Folding carton packaging is used across industries with different regulatory, functional, and branding requirements. Packaging solutions are often adapted by industry to support product protection, retail presentation, and supply chain needs.

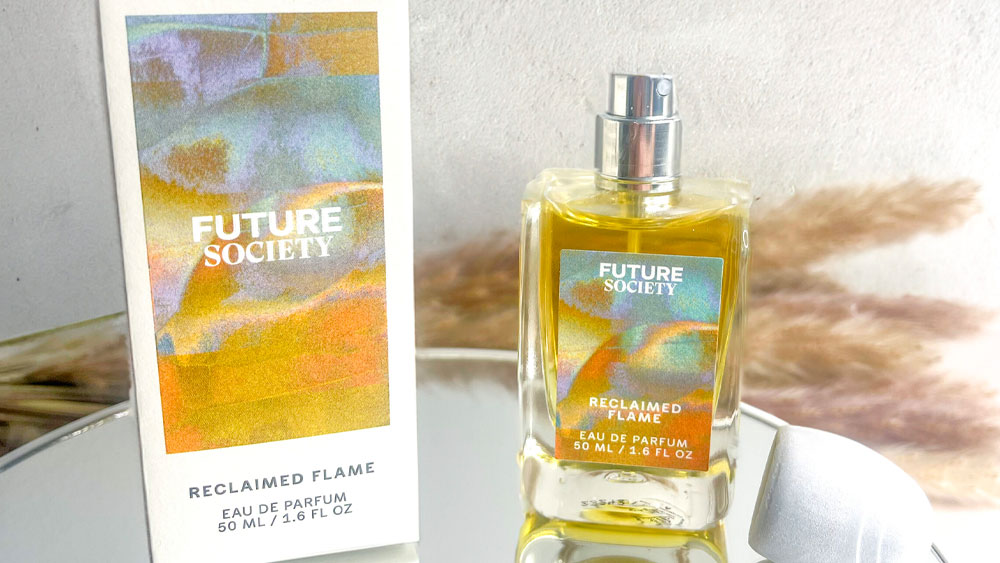

Beauty & Personal Care

Carton packaging designed to support brand presentation, product protection, and premium unboxing experiences.

Food & Beverage

Folding cartons designed to maintain product integrity, support freshness, and perform in retail environments.

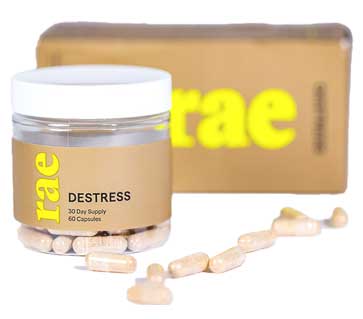

Wellness & Supplements

Carton designs that balance protection, labeling clarity, and visual consistency across product lines.

RFID Packaging

Smart folding cartons that integrate RFID features to support supply chain visibility, inventory management, and retail compliance.

Capabilities That Support Folding Carton Packaging

Folding carton packaging programs are supported by a combination of printing, converting, and quality controls to ensure consistency across design variations and production volumes.

Common capabilities that support folding carton solutions include:

- Offset and digital printing for a range of artwork and run sizes

- Precision die cutting, folding, and gluing

- Color management to support brand consistency

- Flexibility to support both shorter runs and scaled programs

For details on production processes and capacity, view our folding carton manufacturing page.

Frequently Asked Questions about Folding Cartons

Folding Carton Insights & Resources

U.S. Packaging and Labeling Requirements: FDA, FTC, and FPLA Explained

How PCR Packaging Supports Your Goals and Your Customers’ Expectations

16 pt vs 28 pt Cartons: How to Choose the Right Thickness for Your Carton Packaging

Certifications & Accreditations

The EcoVadis Bronze certification is a rating awarded to companies that rank within the top 35% of all companies for their overall sustainability performance. It indicates a strong awareness of social and environmental impacts, a commitment to continuous improvement, and a structured approach to sustainability management across environmental, labor, ethics, and sustainable procurement criteria.

A Sustainable Green Printing Partnership (SGP) certification is a comprehensive, third-party validation for print and packaging facilities that meet high environmental standards and demonstrate best practices for sustainability across their entire operations. This certification involves a comprehensive audit to ensure a facility reduces waste and energy consumption, transitions to sustainable materials, creates safer workplaces, and maintains a strong sustainability management system.

The Great Printer Environmental Initiative Program recognizes printers who exceed required mandates in compliance with all Environmental, Health, and Safety (EHS) rules, regulations, and laws. Great Printers demonstrate their commitment to minimizing their impact on human health and the environment while producing quality printed products.

Last Updated on February 20, 2026