What Are RFID Labels? Benefits, Types, How They Work

In the packaging and supply chain management industry, technological advancements continually redefine operational standards. Among these innovations, RFID labels offer various accuracy, efficiency, and security benefits.

Utilizing radio frequencies, RFID labels transcend traditional barcode systems, offering real-time tracking capabilities and robust anti-counterfeiting measures. The system updates all those involved in the logistical process regarding the whereabouts of a tagged item, ensuring that it arrives at its intended destination.

From seamless inventory management to the fortification against counterfeiting, there is more to know about RFID labels and how they work. Discover more information from the infographic below.

Jump to a Section:

- What Are RFID Labels?

- 5 Benefits of RFID Labels

- Types of RFID Tags

- Types of RFID Systems

- Common RFID Applications

- How to Choose the Right RFID Label: 5 Factors to Consider

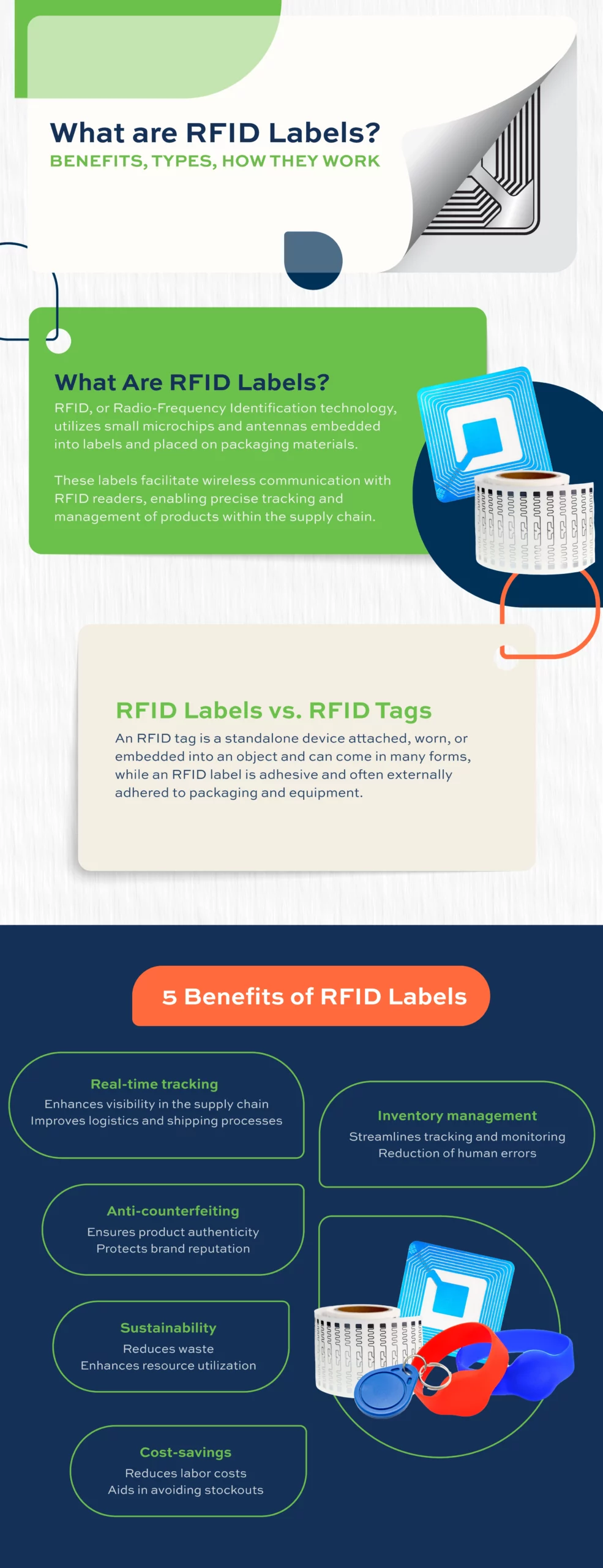

What Are RFID Labels?

RFID labels, or Radio-Frequency Identification labels, are advanced identification and tracking devices that use a tiny microchip and an antenna. The technology uses electromagnetic coupling to transmit data between labels and RFID readers.

The microchip within the product label stores unique identification data related to the tagged item, while the antenna facilitates communication with RFID readers. This wireless interaction allows real-time tracking and monitoring of products within the supply chain.

Unlike traditional barcodes, RFID labels do not require direct line-of-sight scanning, allowing quick and efficient data capture.

RFID labels have various applications across different industries, providing enhanced efficiency, accuracy, and security benefits. Beyond logistics, they play a crucial role in streamlining inventory management and providing real-time insights into the status of items throughout their journey.

RFID labels vs. RFID tags

RFID labels and tags are distinguished primarily in their form and application. While both have microchips and antennae, RFID tags are devices that one can attach directly to products or assets or wear on their person.

In contrast, RFID labels incorporate RFID technology into packaging materials and are usually adhesive and flexible. One can use RFID tags as independent devices, whereas labels are part of the packaging design.

5 Benefits of RFID Labels

RFID labels offer a plethora of benefits across various industries. These include:

1. Real-time tracking

RFID labels enhance supply chain visibility by providing real-time product tracking. This heightened visibility enables businesses to monitor the movement of items at every stage, identify potential delays, and ensure timely deliveries.

Utilizing the technology ultimately improves operational efficiency and customer satisfaction. Buyers have their expectations set on deliveries and can appreciate transparency, fostering trust in the company.

2. Inventory management

With RFID technology, businesses can accurately track the location and quantity of items, minimizing having to note each down manually and reducing the likelihood of human errors. This enhanced accuracy leads to improved inventory control, optimized stock levels, and increased efficiency in warehouse operations, ultimately translating to improved productivity.

3. Anti-counterfeiting

The labels are crucial in ensuring item authenticity and protecting brand reputation. With unique identification data embedded into RFID tags, one can verify the authenticity of products and detect if counterfeit goods slipped into the supply chain.

This method helps safeguard brand integrity as it mitigates the risk of customers receiving low-quality imitations and assures them of the quality of one’s items.

4. Cost-savings

Automating tracking and monitoring processes with RFID technology eliminates the need for manual inventory counts. It reduces labor-intensive tasks such as manual recording and counting.

A business can also maintain optimal stock levels by tracking supply and demand, avoiding stockouts, and reducing the costs associated with overstocking or understocking inventory.

5. Sustainability

Unlike traditional labeling systems that often rely on paper-based tags and documentation, RFID labels leverage digital data encoding. This shift toward digital information reduces reliance on paper. It minimizes the environmental impact of paper production, printing, and disposal.

Specific label designs also take into account recyclability. For instance, companies can break down the metal in the antennae. However, the lithium batteries inside require more care and different processes.

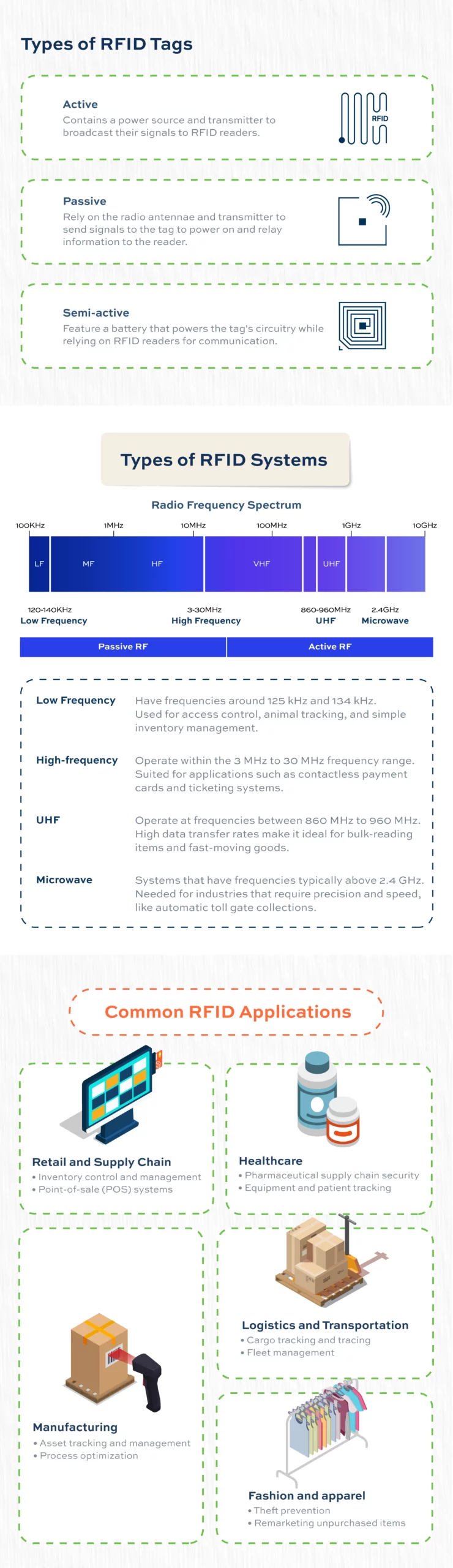

Types of RFID Tags

Understanding the diverse types of RFID tags is crucial for tailoring custom packaging solutions to operational needs. There are three types, which are:

Active

An internal battery powers active RFID tags, constantly transmitting signals over long distances. These tags are suitable for real-time tracking of high-value assets, such as shipping containers, vehicles, and equipment, where extended read ranges and frequent updates are essential.

Due to their enhanced visibility and monitoring capabilities, active RFID tags are common in logistics, transportation, and supply chain processes.

Passive

Passive RFID tags do not have an internal power source and rely on RFID reader signals for activation. These tags are more cost-effective than their active counterparts and are also compact.

Passive tags are ideal for scenarios where frequent battery replacement or maintenance is impractical, such as for products in a retail store or entry control like access cards. Their simplicity and affordability make them a preferred choice for various industries, offering reliable and efficient item identification.

Semi-active

Semi-active RFID tags, also known as battery-assisted passive (BAP) tags, balance the abilities of active and passive devices. These tags use a small battery to power the chip but need readers to communicate the information they contain.

Being a cross of two types means enhancing read range and reliability while maintaining a more extended operational life than fully active tags.

Semi-active tags are well-suited for healthcare and food product transportation applications like temperature monitoring. Some companies can also use them for tracking environmental conditions such as humidity.

Types of RFID Systems

As there are different types of RFID tags, so are there various types of systems. Each is distinct in what they can offer and their applications. These are:

Low-frequency

Low-frequency RFID systems operate in the frequency range of 30 kHz to 300 kHz. They employ inductive coupling between the RFID reader and the tag, making them less susceptible to interference from liquids and metals.

This system is for short-range applications such as access control and animal tracking. The architecture includes a reader emitting an electromagnetic field, which powers the LF tags in proximity (around 3-5 feet), transmitting the data.

However, remember that it is very difficult for low-frequency systems to read several tags simultaneously as they have little to no anti-collision properties.

High-frequency

This RFID system utilizes electromagnetic coupling for communication between the reader and the tag and functions in 3 MHz to 30 MHz frequencies. Its read range is shorter than LF RFID, at only 1-3 feet.

One notable application of high-frequency RFID is contactless smart cards, providing a convenient and secure method for electronic payments and ticketing systems, allowing for seamless public transportation or event transactions.

UHF

Also known as ultra-high-frequency, RFIDs that use this structure have frequencies of 860 MHz to 960 MHz, yielding longer read ranges (up to 30 feet) than the previous two types. Due to the speed of information transfer, UHF excels in handling large volumes of tagged items for industries relying on retail inventory management or warehouse logistics.

Microwave

Boasting a read range of up to 300 feet and operating at frequencies above 2.4 GHz, microwave RFID systems have the highest data transfer rate.

Microwave RFID’s higher frequency and faster data transfer rates contribute to increased precision in tracking so that tags transmit information in real time.

In automotive manufacturing, for instance, companies can employ this system to track vehicles and components throughout the production process for efficient assembly line operations. Another example is the aerospace industry, where teams can use microwave RFID to monitor critical components’ movement within a facility.

Common RFID Applications

RFID labels have become integral to many industries, revolutionizing different processes. Here are some of the sectors embracing their benefits:

1. Retail and supply chain

RFID labels integrated into product packaging streamline inventory management, offering real-time visibility into stock levels, allowing stores to track products and accurately reduce instances of stockouts or overstocking.

Due to the adhesive nature of the label design, store employees can also trace those they put up on displays and replace them if they sell an item.

Furthermore, RFID-enabled point-of-sale (POS) systems allow for seamless and efficient checkout experiences, as they can automatically check items without the need for cashiers to manually scan barcodes, improving customer satisfaction and reducing waiting times.

2. Healthcare

In the healthcare sector, RFID labels contribute to pharmaceutical supply chain security by enabling the tracking and authentication of medications throughout the distribution process.

It also facilitates equipment management so healthcare facilities can effectively trace the use of medical devices and supplies and improve patient safety by accurately monitoring their movements within their halls.

3. Manufacturing

Asset tracking and management within the manufacturing industry also use RFID labels, as businesses must monitor and locate expensive machinery, tools, and components.

The technology aids in process optimization by providing visibility into the production process, allowing manufacturers to identify bottlenecks and streamline workflows for improved productivity and cost savings.

4. Logistics and transportation

In logistics and transportation, RFID labels aid in cargo tracking and tracing, granting companies the ability to monitor the movement of packages throughout the supply chain. This capability reduces the risk of loss or theft. It facilitates fleet management by providing real-time data on vehicle location and status.

Not only can businesses make timely deliveries, but they can also monitor if their fleet requires maintenance.

5. Fashion and apparel

The fashion industry tends to carry the risk of theft, as they produce high-value items such as designer clothes and jewelry. RFID labels bolster loss prevention efforts by allowing employees to accurately track items throughout the store and even when shipping out orders.

Another purpose that RFID labels serve is in marketing campaigns. Brands can check which items customers did not purchase and remarket them in the future.

How to Choose the Right RFID Label: 5 Factors to Consider

Selecting the correct RFID label is a vital decision for businesses aiming to harness the full potential of RFID technology. Here are some of the factors to consider:

1. Assess durability

Before everything else, a business must assess the durability requirements based on factors such as environmental conditions. This includes temperature variations, moisture levels, and chemical exposure. The selected RFID labels should be capable of withstanding these specific ecological elements to perform consistently and reliably.

Specialized materials and coatings may be necessary for the RFID labels to maintain optimal functionality, even in harsh temperature conditions. For instance, RFID labels with water-resistant or waterproof features are critical for areas with high humidity. Moreover, take note of the product’s lifecycle and potential wear and tear throughout.

2. Evaluate the read range

Determining the required read range is vital for effective tracking and monitoring. The layout of the warehouse space and the speed of item movement during shipping will affect how the labels transmit data to their readers.

The proper read range reduces error rates in tracking and monitoring processes, minimizing missed or inaccurate information.

3. Determine cost-efficiency

The upfront costs associated with RFID label implementation include purchasing RFID tags, readers, and the required software infrastructure. A careful assessment of these initial expenses helps determine the financial commitment needed to adopt the technology.

There’s also the Total Cost of Ownership (TCO) analysis, which considers ongoing expenses such as maintenance, training, and potential upgrades. By accounting for the entire lifecycle, businesses gain insights into the financial implications over an extended period.

4. Choose the right form factor

Each RFID type, whether passive, active, or semi-active, offers distinct advantages that align with specific sectors and operational requirements. Understanding their strengths and limitations can help them make strategic choices that align with business goals.

Remember to choose the appropriate size, shape, and mounting option of the RFID label to suit the product and its packaging. Consider factors such as available surface area, material compatibility, and aesthetic requirements.

Different RFID labels find optimal application in various industries and will significantly impact workflows. Passive RFIDs are more suited for retail due to their low frequencies, while companies needing precise location tracking prefer to use active RFIDs.

5. Ensure compatibility with existing systems

When RFID labels seamlessly integrate with current software platforms and infrastructure, businesses can avoid costly and time-consuming development efforts associated with software modifications or upgrades.

It also minimizes the learning curves for personnel operating the RFID technology. Employees can quickly adapt to the new technology without extensive training or relearning processes, which means fewer disruptions in operations and errors.

In every situation, it’s crucial to assess the effectiveness, affordability, and suitability of each type of RFID.

RFID Labels Lead the Way

RFID labels are reshaping the way businesses approach efficiency. The technology offers numerous advantages, from real-time tracking and meticulous inventory management to robust anti-counterfeiting measures and substantial cost savings.

For pressure sensitive labels and more information about RFID packaging and labels, Meyers is your partner. Our tailored approach considers what your company needs and ensures it’s eco-friendly and sustainable.

Connect with the experts at Meyers today to learn more about our professional printing solutions.