What is Packaging Automation? How It Benefits your Food Brand

Innovation and efficiency have critical roles in the food industry landscape. One crucial aspect that has revolutionized the packaging processes for food brands is automation. As consumer demands evolve and the industry strives for heightened sustainability and faster production, packaging automation emerges as an ideal solution.

The key driving force behind the adoption of packaging automation is the pursuit of efficiency, cost-effectiveness, and improved overall quality. As technology advances, the capabilities of automated systems evolve, offering innovative solutions that redefine the way food brands approach product packaging.

From the streamlined processes of filling and labeling to the integration of cutting-edge robotics, this article will explore the principles that make packaging automation a game-changer for food brands.

What is Food Packaging Automation?

Packaging automation is a technological solution that involves the use of machinery, robotics, and advanced systems to streamline and optimize various aspects of the packaging process. In the context of the food industry, where precision, efficiency, and adherence to quality standards are paramount, packaging automation can help enhance overall operations.

At its core, packaging automation encompasses a range of activities, from filling and labeling to sealing and palletizing, that traditionally required manual intervention. By deploying automated systems, these tasks are not only expedited but also executed with a level of precision that surpasses what human hands can achieve consistently.

However, packaging automation is not a one-size-fits-all concept; it involves tailoring systems to meet the specific needs and intricacies of different products and packaging formats. Whether it’s the packaging of perishable goods or ensuring the integrity of delicate products, automation systems can be customized to handle diverse challenges.

The Fundamentals of Food Packaging Automation

The principles governing packaging automation are designed to address the challenges and complexities inherent in the packaging process. The following are some automated functions that redefine the efficiency and precision of food packaging:

Automated filling processes

One of the fundamental tasks in food packaging is the precise and consistent filling of containers. Automation in this realm involves sophisticated machinery capable of metering and dispensing precise quantities of products. From liquids to granular materials, automated filling processes not only ensure accuracy but also significantly reduce the margin of error associated with manual filling.

Automated labeling systems

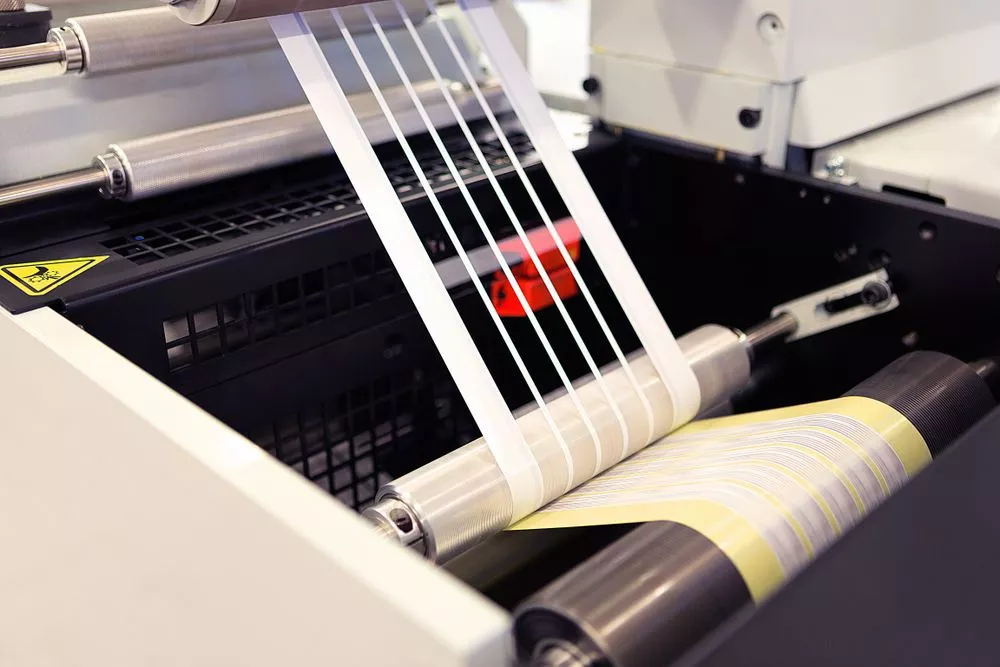

In a visually driven market, accurate and appealing product labeling is essential. Automated labeling systems employ cutting-edge technologies, such as computer vision and machine learning, to apply product labels with unparalleled precision. These systems can adapt to various packaging formats, ensuring that each product receives its designated label seamlessly.

Automated sealing technologies

The integrity and shelf life of food products heavily depend on effective sealing. Automation in this aspect introduces advanced sealing technologies that cater to diverse packaging materials. Whether it’s heat sealing for freshness or tamper-evident seals for consumer safety, automated systems provide airtight solutions that minimize the risk of contamination.

Integration of robotics

Robotics plays a pivotal role in the evolution of packaging automation. Robots are employed for tasks ranging from pick-and-place operations to intricate assembly processes. Their dexterity and speed contribute to increased efficiency and allow for the handling of products with varying shapes, sizes, and fragility.

Key Components of Automation in Food Packaging

With food packaging automation, technology is not a monolithic entity but an integration of key components designed to address the diverse needs of the industry. Each element contributes to the overall efficiency, sustainability, and quality control within the realm of food packaging.

1. Customization and flexibility

Food products come in an array of shapes, sizes, and packaging requirements. Automation thrives on customization and adaptability. Systems are designed to handle various packaging formats, ensuring that the automated process can seamlessly accommodate the unique characteristics of each food product. This level of customization not only enhances efficiency but also allows for a more diversified product portfolio.

2. Sustainable practices

Sustainability is a pressing concern in the modern food industry, and packaging automation aligns itself with eco-friendly practices. The use of Post-Consumer Recycled (PCR) plastic bottles is a notable example. Automated systems can handle the intricacies of using recycled materials, contributing to reduced environmental impact while maintaining the necessary quality standards.

3. Technology and food safety

Food safety is non-negotiable, and automation leverages technology to enhance safety measures. Automated systems utilize sensors and monitoring devices to ensure that food products are free from contaminants. From real-time quality checks to traceability features, technology plays a crucial role in upholding the highest standards of food safety throughout the packaging process.

4. Quality control measures

Maintaining consistent product quality is a hallmark of successful food brands, and packaging automation acts as a guardian of quality control. Automated inspection systems employ advanced technologies, such as machine vision and sensors, to detect anomalies in packaging, ensuring that only products meeting predefined quality criteria reach the market. This not only safeguards the brand’s reputation but also enhances consumer trust.

5 Benefits of Packaging Automation for Food Brands

Food packaging automation has contributed to transformative changes in the competitive food industry. It offers various benefits for brands that extend beyond mere operational efficiency.

1. Increased efficiency in production

One of the most immediate and impactful benefits of packaging automation is the increase in production efficiency. Automated systems operate seamlessly, minimizing downtime, reducing human error, and ensuring a consistent pace of production. The streamlined processes contribute to higher output rates, enabling food brands to meet growing consumer demands with unparalleled efficiency.

2. Cost reduction through labor efficiency

Automation in the packaging industry translates to reduced dependency on manual labor, leading to significant cost savings for food brands. By automating repetitive and labor-intensive tasks, companies can allocate human resources to more strategic roles while simultaneously cutting down on expenses related to wages, training, and employee turnover.

3. Enhanced product quality and consistency

Consistency in product quality is a hallmark of successful brands, and packaging automation serves as a guardian of this critical aspect. Automated systems ensure that each product undergoes standardized packaging processes, minimizing variations and deviations. The result is a level of consistency that resonates with consumers, fostering brand loyalty and trust.

4. Accelerated time-to-market for food products

In the fast-paced world of consumer preferences, swift time-to-market is a competitive advantage. Packaging automation expedites the entire packaging process, from design to distribution, reducing lead times significantly. This agility allows food brands to respond promptly to market trends, launch new products, and adapt to changing consumer preferences with unparalleled speed.

5. Reduced environmental impact

Sustainability is a growing concern for both consumers and businesses. Since packaging automation contributes to efficient material utilization, this helps reduce the environmental footprint of food packaging. The optimized processes when producing PCR packaging, for instance, result in less waste, and the incorporation of sustainable practices aligns with the broader industry shift towards eco-friendly solutions.

Pioneering Excellence through Packaging Automation

From heightened efficiency and reduced labor costs to an unwavering commitment to product quality and sustainability, automation reshapes how businesses can execute food packaging processes.

Embracing packaging automation can be not only a choice but also a strategic imperative for food brands. The accelerated time-to-market, coupled with the environmental consciousness inherent in sustainable practices, positions automation as the cornerstone of success in the competitive food landscape.

For food brands aspiring to pioneer excellence and stay ahead in an ever-changing market, discover innovative custom packaging solutions at Meyers. Contact our experts and propel your brand into a realm of efficiency, quality, and sustainability like never before.