A Guide to Folding Cartons: Benefits, Types, Design Basics

In a fast-paced consumer market, packaging has transcended its traditional role as a mere box or container for products. Its design captures consumer attention, influences purchasing decisions, and elevates brand image. Businesses can choose from a myriad of packaging options, but one solution that is gaining market momentum is folding cartons.

Folding cartons are highly versatile and cost-effective packaging solutions allowing businesses to showcase their brand uniquely. Manufactured with paperboard, folding carton packaging are highly sustainable, allowing companies to reduce their environmental impact and meet modern consumer needs.

As the demand for eye-catching and sustainable packaging solutions grows, understanding the basics of folding cartons can give brands a competitive advantage. Learn how to leverage folding cartons’ benefits to enhance your brand image and attract more customers.

Jump to a Section:

- What are Folding Cartons?

- The Folding Carton Market: Statistics and Packaging Trends

- 4 Benefits of Folding Carton Packaging

- 6 Types of Folding Cartons

- Folding Carton Design Basics

What are Folding Cartons?

Folding cartons serve as containers for items and products to protect them from the surrounding environment, showcase the brand, and simplify product shipping. Folding carton materials come in paperboards of different types, such as coated unbleached kraft (CUK), non-bending chipboard, and premium grade solid bleached sulfate (SBS).

Through product packaging designs, businesses can print key brand visuals and eye-catching aesthetics onto folding cartons to include them in their marketing and branding initiatives.

Industries worldwide have used folding cartons in various ways to package and sell their products to their customers. The pharmaceutical industry, for instance, has used folding cartons for its medical packaging needs and to protect drugs, medicines, and other medical products from contamination.

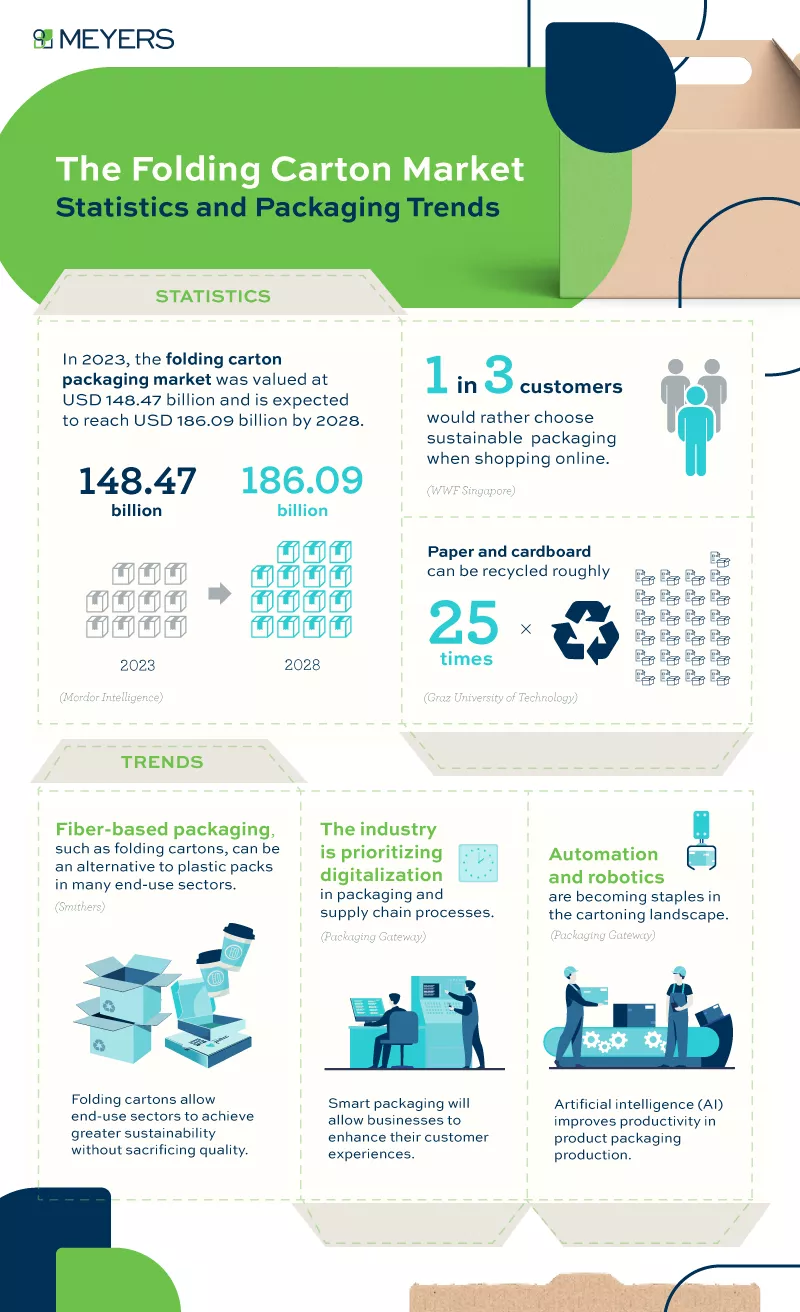

The Folding Carton Market Statistics and Packaging Trends

Folding cartons are ever-changing, with businesses continuing to innovate their design and how they use it. It’s essential to stay updated on the industry to deliver better and more relevant product experiences to clients and customers.

Folding Carton Statistics

- In 2023, the folding carton packaging market was valued at USD 148.47 billion and is expected to reach USD 186.09 billion by 2028. (Mordor Intelligence)

The steady growth of the folding carton market underscores how it’s an industry that brands must not overlook in the years to come.

- One in three customers would rather choose sustainable packaging when shopping online. (WWF Singapore)

This statistic highlights how popular sustainability advocacies have become, especially in Southeast Asia. Businesses must now begin offering sustainable packaging options, such as folding cartons, for their eCommerce customers to meet changing customer demands and expectations.

- Paper and cardboard can be recycled roughly 25 times (Graz University of Technology)

Given that folding cartons are designed with paperboard, businesses can expect a significant return on investment with how recyclable the material is. This product packaging aspect can also prolong brand engagement as customers repurpose them for daily use, such as storing valuables.

Folding Carton Trends

- Fiber-based packaging, such as folding cartons, can be an alternative to plastic packs in many end-use sectors. (Smithers)

Sustainable folding cartons offer businesses environmentally friendly packaging without compromising quality or strength.

- The industry is prioritizing digitalization in packaging and supply chain processes. (Packaging Gateway)

More brands include QR codes in their packaging, enabling customers to scan them for additional product information. This smart packaging feature provides valuable details like manufacturing processes and nutritional value, enhancing the overall customer experience.

- Automation and robotics are becoming staples in the cartoning landscape. (Packaging Strategies)

Artificial intelligence (AI) is making its way into the packaging industry. These cutting-edge technologies allow businesses to reduce production times, improve efficiency, and deliver greater value to their clients and customers.

Discover more packaging trends:

4 Benefits of Folding Carton Packaging

Folding cartons are so popular in the industry because they provide businesses with the following benefits.

1. Easily customizable

Making custom folding cartons is straightforward because the medium is highly versatile.

For instance, folding cartons for cosmetics can feature different coating types to convey sophistication in their branding. On the other hand, food packaging folding cartons, such as cereal boxes, may adopt vibrant colors and captivating visuals to grab children’s attention along grocery store aisles.

2. Environmentally friendly

Paper folding cartons are excellent packaging choices for brands wanting to become more environmentally friendly. Concerns about the durability of this paper-based packaging are unfounded, as these cartons remain sturdy while minimizing waste since brands can design them from a single sheet.

3. Cost-effective

Paperboard is a cost-effective alternative to glass or metal for packaging. Since producing high orders of folding cartons is so simple, it’s an economical option for businesses looking to minimize expenses without compromising quality. The cost of sustainable packaging is also low, which is excellent for companies that want to be more eco-friendly on a budget.

4. Space-efficient

Folding cartons are lightweight packaging options that are easily stackable, which makes transport and shipping much easier. The efficient use of space, especially with reverse tuck folding carton boxes, allows companies to optimize packaging density and reduce logistical costs by accommodating more packages per trip.

These benefits apply to the different types of folding cartons.

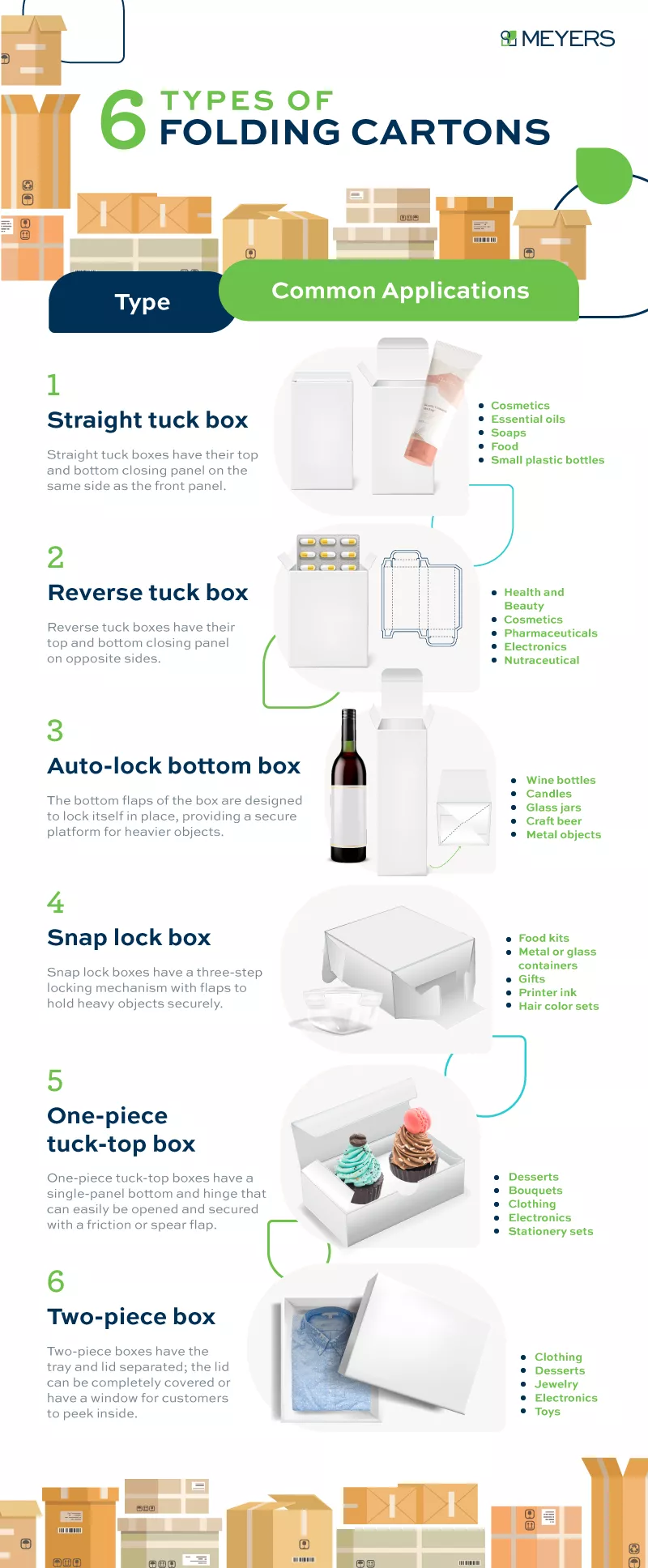

6 Types of Folding Cartons

While different types of folding cartons share similar elements, each has strengths and weaknesses. Below are a few examples of the different types of folding cartons brands can consider for their products.

1. Straight tuck box

In the straight tuck box design, the top and bottom closing tuck panels are placed on the same side as its front panel, creating a sleek and clean packaging design. This style is commonly used for various products, including cosmetics, soaps, and pharmaceutical products.

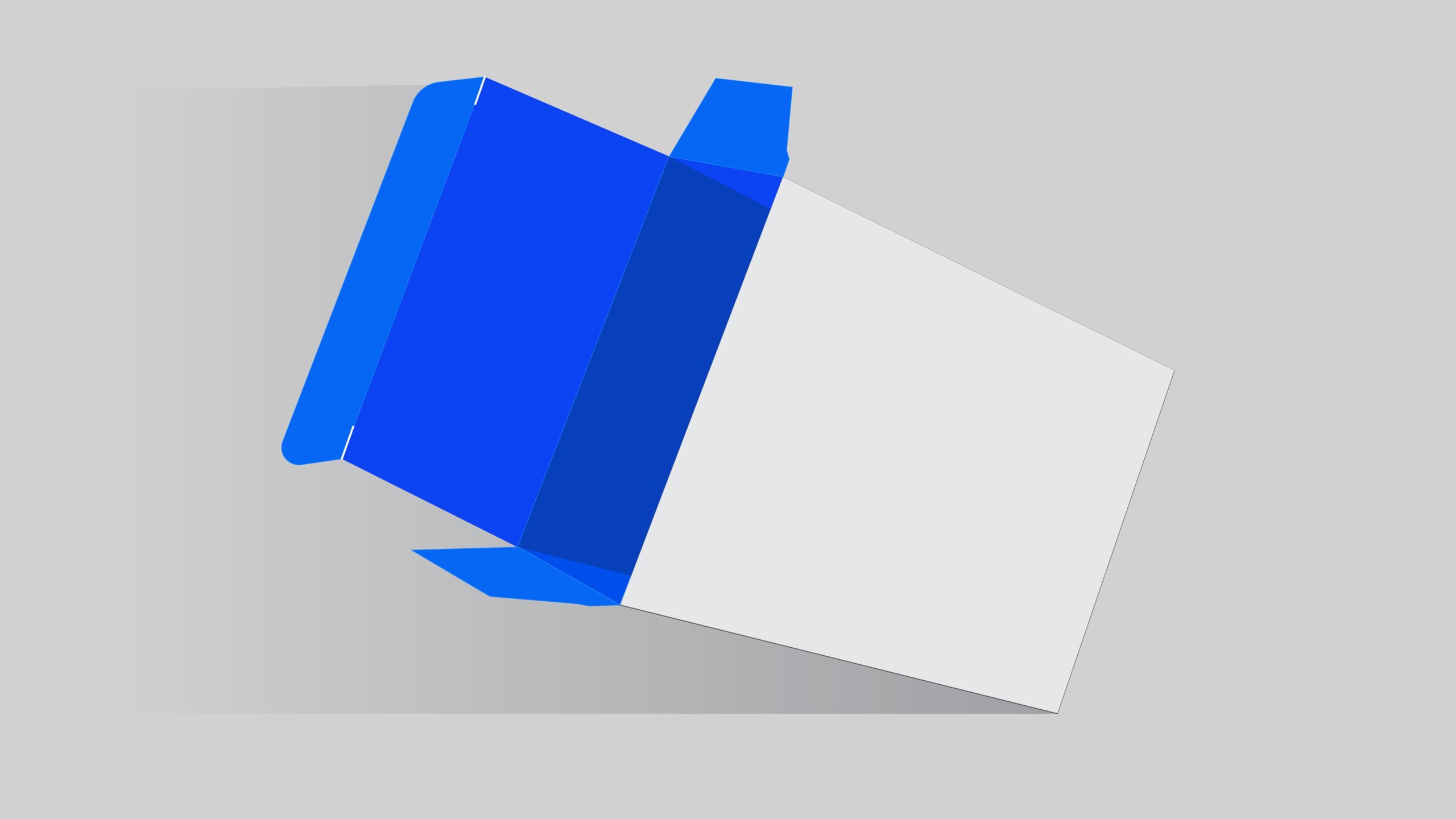

2. Reverse tuck box

Reverse tuck boxes share a similar design to straight tuck boxes except for the placement of their tuck panels. The closing panels of reverse tuck box folding cartons are on opposite sides. The top closing tuck panel aligns with the front panel, folding towards the back of the carton, while the bottom panel closes towards the front.

Some companies prefer reverse tuck boxes because they can accommodate more cartons per sheet, resulting in a lower price per sheet and increased value. The individual designs of these folding cartons fit together similarly to jigsaw puzzles, which helps businesses maximize the space for printing and transport.

3. Auto-lock bottom box

Auto-lock bottom boxes are also known as crash bottom boxes. Carton manufacturers and other industry professionals often deem it to be the strongest folding carton to use. Its bottom doesn’t require additional flaps or tape to lock in place and be secure during assembly; its design allows it to tuck itself in place.

Businesses receive these boxes flat, with the bottom already pre-folded. Pushing the sides of the box to widen the lid will trigger the auto-locking mechanism. This design allows the carton to securely hold heavier objects, such as candles or wine bottles, preventing them from falling through.

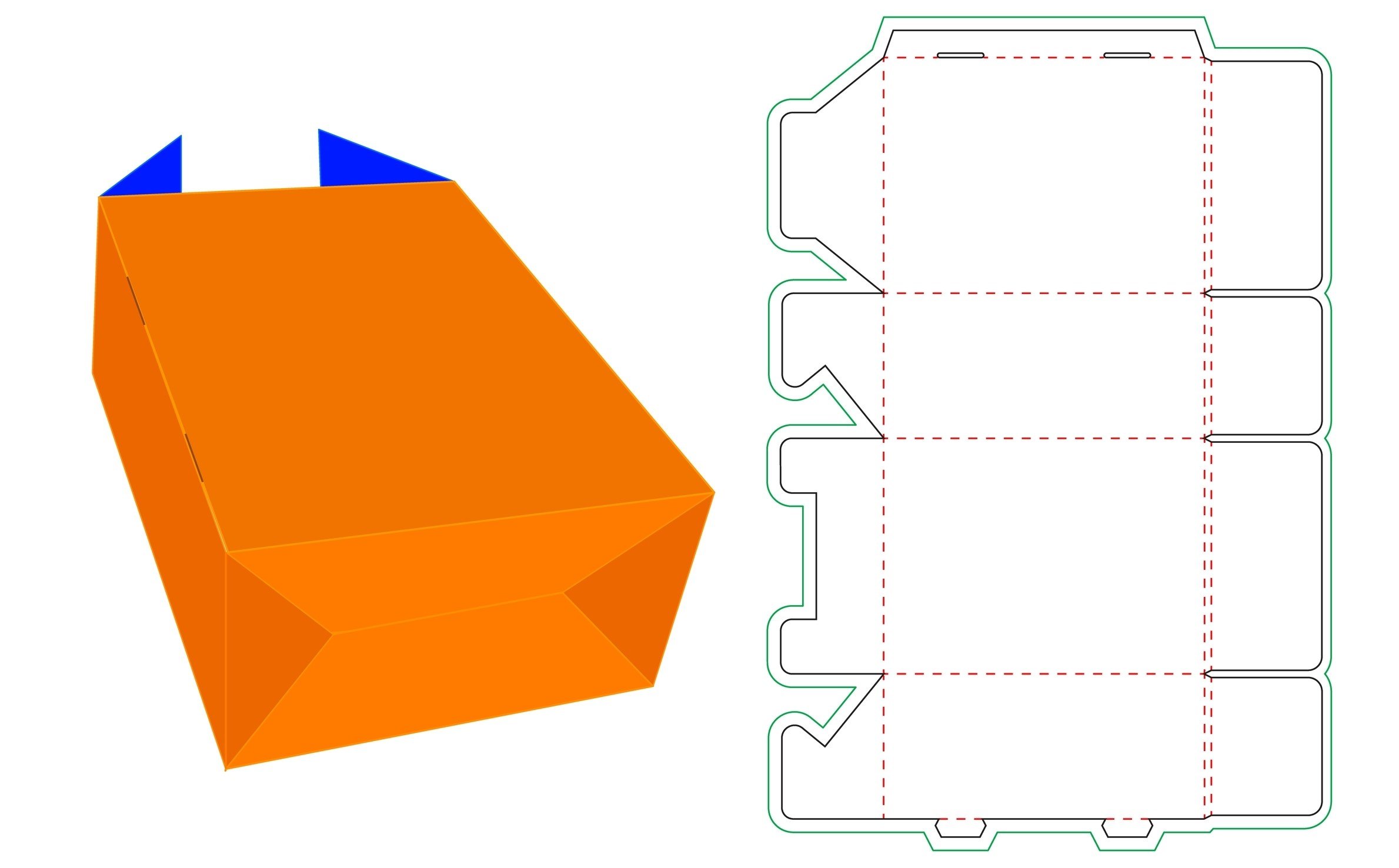

4. Snap bottom lock box

Snap bottom lock boxes combine the functionalities of an auto-lock flap and a regular tuck-in flap. Some professionals may also refer to these boxes as 1-2-3 bottom boxes because it only takes three steps to lock the bottom. It’s ideal for heavier objects, such as glass or metal.

5. One-piece tuck-top box

One-piece tuck-top boxes, resembling mailer boxes, feature a hinged opening with locking flaps for secure transportation. The flat bottom and double-sided walls improve the box’s sturdiness. Typically, these boxes use a friction lock for the tuck-top; however, some variants may utilize an anchor or spear lock for added security.

Businesses often use these boxes for donuts, clothing, and bouquets, to name a few.

6. Two-piece box

Two-piece boxes have a tray and lid that are separate from each other. Some lids have a covered design that brands can customize with their visual identity. These lids are most common for luxurious fashion items, desserts, and jewelry.

Others can have a portion of the lid to have a window, giving customers a peek at what’s in the box. Window lids are popular for products that range from baked goods to toys.

Folding Carton Design Basics

Despite folding cartons having different appearances, they share a few fundamental aspects. Brands must learn what goes into folding carton design to understand how they may customize them to fit their needs. The process is generally divided into three parts.

Elements

Before printing can begin, businesses must establish the following aspects of the folding carton project.

1. Shape and size considerations

When selecting a folding carton, businesses must consider the size requirements based on the product to be packaged. For instance, packaging wine may not necessitate a wide box unless they intend to ship multiple bottles in a one-piece tuck-top box. In such cases, they can lay the bottles on their side to fit more.

2. Structural elements

Folding cartons have multiple components that can vary in appearance, depending on the box design. The primary structural elements are the carton’s panels and flaps. The panels form the sides of the box, while the flaps fold into the box or interlock with each other to secure the design.

Some businesses may choose a double-layered corrugated material, such as a thicker paperboard, to secure a fragile product such as glass jars or to facilitate chilling for frozen goods. On the other hand, for less delicate items, thinner materials, such as plastic medication containers, may be considered sufficient.

3. Graphic design and branding

A business’s packaging design influences how consumers perceive the brand. If the luxurious cosmetic product is packaged in a flimsy and thin folding carton, it can affect how the customer sees the brand.

Businesses must consider how they want audiences to perceive them before designing their folding carton.

Printing Techniques

The different types of printing for packaging have individual pros and cons, with the best process depending on what the business intends to accomplish.

1. Offset printing

Offset printing involves a sequence of rotating cylinders that print the ink onto the material, typically paper. The advantage of offset printing is that businesses can print numerous items quickly. Therefore, it’s the ideal technique for large product orders.

2. Digital printing

Digital printers use inkjet or electrophotographic imaging technologies to print designs onto the given material. Although lithography or flexography produce excellent quality, the final product from industrial digital printing technologies can appear highly premium with offset-comparable quality.

The technique has a minimal setup and quick turnaround times because digital printers do not require printing plates or extensive make-ready processes.

3. Flexography

Flexographic printing is similar to lithographic (offset) printing because the process relies on rotating cylinders’ sequences to apply the ink onto the substrate. This technique is ideal for non-porous materials, including film and foil, which businesses can use for folding carton labels.

Finishes and Effects

Once the initial print is finished, companies can add styles and embellishments to elevate and differentiate their packaging.

1. Embossing and debossing

Certain folding carton designs incorporate raised or depressed sections in the final printed design. These design decisions can add texture, visual interest, and depth to the product packaging, contributing to branding efforts and influencing customer perceptions. Businesses often use these features to make their designs or logo more prominent.

2. Foil stamping

Foil stamps can give products a luxurious flair. These types of printing glisten under the light and can draw customers’ eyes to certain accents, texts, or logos.

3. Spot UV coating

Spot UV coating can help add contrast to a folding carton’s textures. Glossy spot coatings reflect light, giving portions of the packaging design a shiny accent. Matte spot coatings are better at absorbing light, enriching the design with a texture that’s soft to the touch.

4. Varnishes and laminates

Varnishes and laminates help give folding carton designs a sheen that can elevate a product’s branding. Glossy varnishes can help make the colors of a packaging design more vibrant, enhancing its quality.

Laminates add a layer to the folding carton’s packaging to better secure the product inside.

5. Die Cutting

Die cutting is the process where businesses can create high volumes of custom and unique folding carton boxes. Companies must create a design to place onto a die, similar to a mold or template. Operators then feed large sheets of material, such as paperboard, into the machine, automatically cutting them into a custom shape.

Learn more about enhancing your folding carton designs:

- Styles and Embellishments to Improve Folding Carton Designs

- Elevate Your Packaging: Folding Carton Trends & Design Tips

Elevate Your Packaging with Folding Cartons

Folding carton boxes do more than contain objects and products. These packaging types play a role in a customer’s experience with a brand.

As businesses navigate the ever-changing packaging landscape, understanding the benefits, types, and design basics of folding cartons becomes essential. Brands can elevate their product packaging strategies and make a lasting impression on consumers.

Partner with Meyers, a professional product packaging manufacturer, to enhance your packaging solutions with industry-standard printing services tailored to your needs. Contact Meyers experts today to learn how to leverage the right folding cartons for your business.